+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

As we look ahead to 2026, the landscape of hydraulic oil cylinder technology is evolving at a rapid pace. Innovations are transforming industries that rely on these critical components. Companies are investing heavily in research to enhance performance and efficiency. This includes the development of more durable materials and advanced sealing technologies, ensuring longer lifespans and reduced maintenance.

Emerging trends highlight the importance of sustainability. Many firms are exploring bio-based hydraulic fluids. This shift not only improves environmental impact but also meets stringent regulations. Yet, some challenges remain. The integration of smart technology into hydraulic systems is exciting but may introduce complexity that requires careful implementation.

Understanding these trends will be crucial for engineers and manufacturers. They must navigate this landscape effectively. Hydraulic oil cylinders are at the core of many systems, and their innovations will shape the future of manufacturing and other sectors. Keeping track of these developments will better prepare businesses for the challenges ahead.

Hydraulic oil cylinder design is evolving rapidly. Emerging technologies are shaping the future of this industry. For instance, smart sensors are now integrated into cylinders. These sensors can monitor pressure, temperature, and performance in real time. Reports indicate that this technology boosts operational efficiency by up to 30%.

Another trend is the use of advanced materials. Lightweight composites are replacing traditional metals. They reduce weight without sacrificing strength. A recent study showed that using these materials can improve energy efficiency by 20%. However, some engineers express concerns over durability and long-term performance.

Furthermore, manufacturers are focusing on sustainability. Eco-friendly hydraulic fluids are gaining traction. These fluids minimize environmental impact while maintaining performance. Yet, there is still a need for more research. The transition must balance performance and ecological considerations. Exploring these innovations raises questions about scalability and cost-effectiveness. The industry stands at a crucial juncture, poised between innovation and practical challenges.

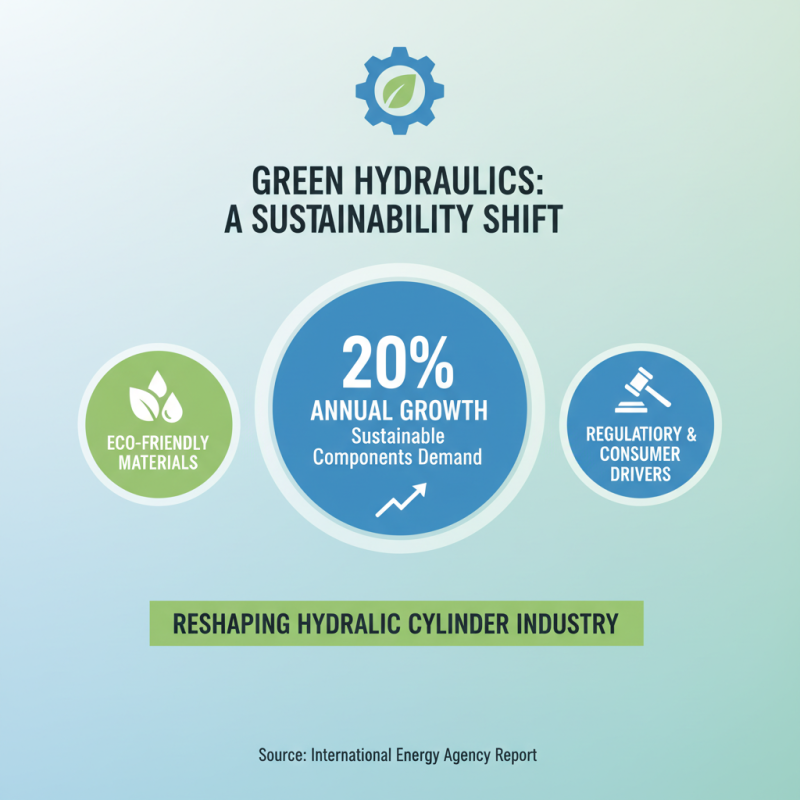

The shift towards sustainability is reshaping the hydraulic oil cylinder industry. Companies are increasingly prioritizing eco-friendly materials. According to a recent report from the International Energy Agency, the demand for sustainable hydraulic components is expected to grow by 20% annually over the next five years. This trend is driven by regulatory pressures and consumer expectations.

New materials, such as bio-based oils and recycled metals, enhance sustainability. Research indicates that hydraulic cylinders made from these materials can reduce carbon footprints by up to 30%. However, challenges remain. Not all bio-based hydraulic fluids perform well under extreme conditions. Companies must balance performance with sustainability.

Moreover, the lifecycle of hydraulic oil cylinders is often overlooked. Many manufacturers focus on initial production rather than end-of-life disposal. This oversight can lead to environmental issues. Data from industry surveys show that nearly 40% of hydraulic cylinders are not disposed of responsibly. It highlights the need for a more comprehensive approach to sustainability in the sector.

The integration of IoT and automation into hydraulic oil cylinders is reshaping the industry. Smart hydraulic oil cylinders are more than just tools. They are becoming intelligent systems that collect data in real time. This data can monitor performance and detect problems early. Sensors embedded in these cylinders provide insights previously unavailable.

Automation enhances operational efficiency as well. For example, operators can remotely control these cylinders from anywhere. This boosts productivity and reduces the need for constant human oversight. However, it also raises concerns about reliance on technology. What if a system fails? The consequences could be severe. Operators must maintain a balance between automation and manual control.

Furthermore, there’s a learning curve with these innovations. Employees may need training to effectively use smart cylinders. This transition might disrupt traditional workflows. It’s crucial for companies to address these challenges. Embracing change also means preparing for potential mistakes along the way. Adjustments may be necessary as the technology evolves, and reflection on these outcomes is vital.

The hydraulic oil cylinder industry is evolving rapidly. Various applications are driving these innovations. Construction, agriculture, and manufacturing sectors are leading the change. They demand efficiency and precision. This pushes manufacturers to rethink designs and materials.

In agriculture, for example, precise hydraulic systems increase productivity. While these systems improve output, they can be complex. Users often face difficulties in maintenance. Understanding the intricacies is vital for optimal performance. Training workers is essential to reduce mistakes.

Tips: Regular maintenance checks can prolong cylinder life. Use compatible oil to avoid deterioration. Consider training programs for staff. This investment pays off through enhanced performance. Making small changes can lead to significant benefits in the long run.

| Innovation/Trend | Description | Industry Application | Expected Impact |

|---|---|---|---|

| Smart Hydraulic Systems | Integration of IoT technologies for real-time monitoring and predictive maintenance. | Construction and Manufacturing | Increased operational efficiency and reduced downtime. |

| Energy-efficient Hydraulic Cylinders | Design improvements for reduced energy consumption and enhanced power-to-weight ratios. | Agriculture and Transportation | Lower operating costs and environmental impact. |

| Advanced Materials | Use of lightweight composites and improved seals to enhance durability. | Mining and Heavy Machinery | Extended service life and reduced maintenance costs. |

| Modular Cylinder Designs | Interchangeable components for greater customization and adaptability. | Robotics and Automation | Faster deployment and easier upgrades. |

| High-speed Oil Cylinders | Designs that allow for rapid actuation and cycle times. | Packaging and Material Handling | Increased throughput and productivity. |

The hydraulic cylinder market faces unique challenges in 2026. Sustainability is a primary concern. Many industries are seeking eco-friendly solutions. This shift pushes manufacturers to innovate while reducing environmental impact. As customers become more aware, they demand greener products.

Opportunities also emerge in automation. Advanced technologies are reshaping hydraulic systems. Smart cylinders that integrate with IoT are gaining traction. These can predict maintenance needs. Predictive analytics enhance reliability and operational efficiency. Companies need to adapt to this evolving landscape.

Tips for industry professionals: Focus on R&D to stay competitive. Invest in employee training for new technologies. Networking within the industry can provide insights. Share best practices with peers to tackle common challenges together. Embrace flexibility; market demands change rapidly. A proactive approach will lead to growth and success.

This chart illustrates the projected advancements in hydraulic oil cylinder technology over the next few years, focusing on key trends such as energy efficiency, smart technology integration, and material innovations.