+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

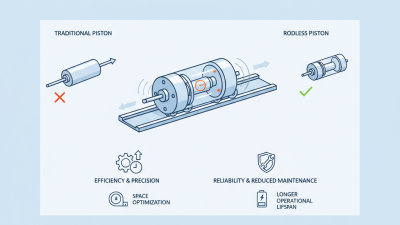

In the realm of modern automation, efficiency is key. Rodless piston cylinders are becoming a leading choice. They provide unique solutions for various applications. Unlike traditional cylinders, these systems lack the external rod, maximizing space. This design improvement can lead to innovative configuration options.

One major advantage of rodless piston technology is versatility. These cylinders can adapt easily to different environments. They often excel in compact setups, where space is limited. As automation needs evolve, rodless piston cylinders rise to meet these challenges. However, not all applications may benefit equally from this technology. It is essential to analyze specific requirements before implementation.

In exploring the top ten benefits of rodless piston cylinders, we uncover their potential. Each benefit sheds light on engineering innovations. For many, these cylinders offer a mix of reliability and performance. Yet, it's important to reflect on their limitations too. Understanding both sides can lead to more informed decisions.

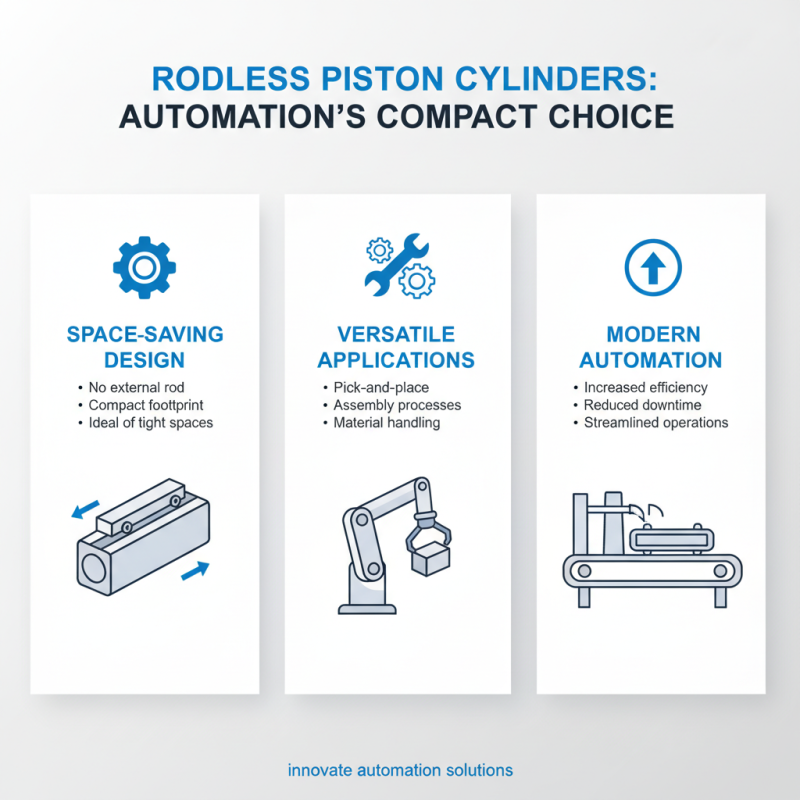

Rodless piston cylinders have emerged as a preferred choice in modern automation applications for several compelling reasons. Their design offers a compact solution for spaces where traditional cylinders might struggle. Without the external rod, these cylinders save significant installation space. This makes them ideal for tight environments, such as manufacturing lines or robotic arms. Furthermore, they are versatile, suitable for various tasks, from simple pick-and-place operations to complex assembly processes.

Another advantage lies in their efficiency. Rodless configurations reduce friction and increase speed. They can achieve faster cycle times, enhancing the productivity of any system. These cylinders are often lighter, which supports faster movement. However, it's essential to understand their limitations. In high-stress applications, they may not perform as effectively as expected. Regular maintenance is crucial, as wear can lead to decreased performance over time. Users should closely monitor their integration in automated systems to ensure optimal results, even as they enjoy the benefits.

Rodless piston cylinders have gained popularity for their space efficiency and compact design. These components offer a streamlined solution for various automation tasks. Their design eliminates the need for external rods, allowing for significant space savings. With a shorter overall length, these cylinders fit easily into tight areas.

Tips: When considering rodless piston cylinders, think about the application. Compact designs are not just for saving space; they can also reduce the total weight of the system. It’s crucial to assess how these factors influence overall performance.

These cylinders have unique features that contribute to their effectiveness. For instance, they provide smooth motion control. However, they require precise alignment during installation. Misalignment can lead to wear and reduce efficiency. Regular maintenance checks can help in identifying potential issues. Making adjustments as needed can extend the life of the cylinders.

Tips: Always keep the environment in mind. Dust and debris can affect performance. Using protective covers can shield your investment and enhance durability. Ensure that your setup allows for easy access to maintenance points. A good layout facilitates timely inspections and repairs, leading to a more reliable automation solution.

Rodless piston cylinders are transforming modern automation. Their design allows for greater speed and responsiveness in an array of applications. According to industry reports, these cylinders can increase cycle times by up to 30%. This efficiency is crucial in sectors like packaging and assembly where speed directly impacts productivity.

A unique feature of rodless designs is their compact structure. This allows for shorter stroke lengths while maintaining high speeds. With minimal space requirements, automation systems can be more flexible. They can adapt to various layouts without compromising performance. Moreover, rodless cylinders achieve faster response times due to reduced inertia. Studies indicate that these cylinders can provide activation times as low as 16 milliseconds.

Despite these benefits, challenges remain. Proper alignment is essential to avoid wear on the internal mechanisms. Misalignment can lead to reduced lifespan and decreased efficiency. Also, the initial setup can be complex, requiring skilled technicians. These factors are important to consider when integrating rodless cylinders into existing systems. They offer significant advantages, but careful planning is key.

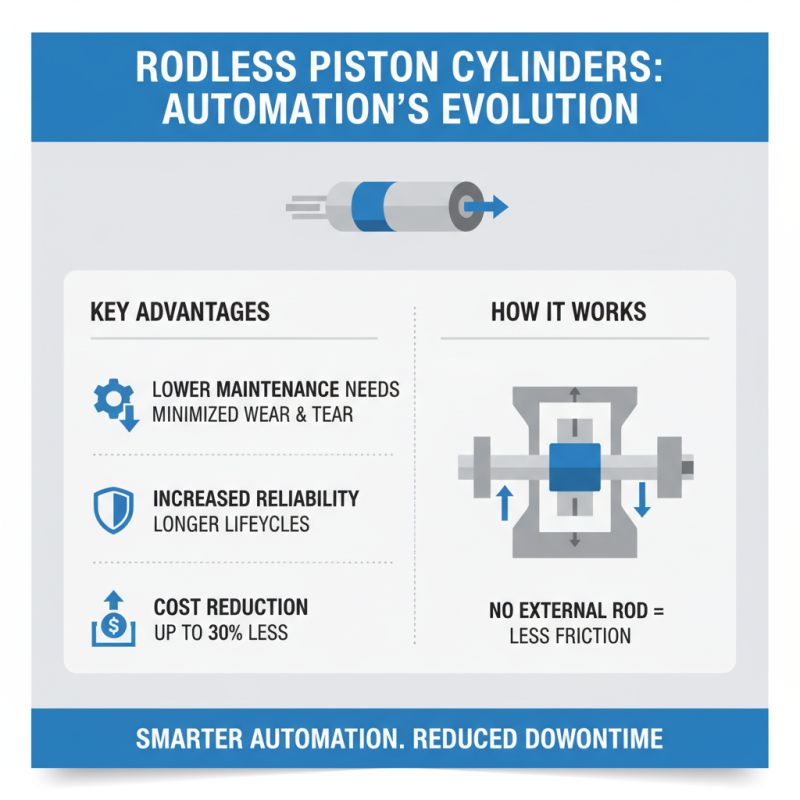

Rodless piston cylinders are becoming increasingly essential in automation solutions. One key advantage is their lower maintenance needs. These systems are designed to minimize wear and tear. Reports suggest that up to 30% of maintenance costs can be reduced through the use of rodless cylinders. The absence of traditional rods decreases friction, resulting in longer lifecycle and reliability.

In environments that demand high performance, these cylinders shine. They are less susceptible to external contamination, allowing for cleaner operations. Less maintenance translates into more uptime. However, if operators overlook regular service checks, potential issues can arise. This could lead to higher repair costs later.

Tip: Regularly monitor the operational performance of your rodless cylinders. Inspect seals and connections often to maintain optimal operation. Keep records of your maintenance activities. Identifying patterns in wear can help prevent unexpected failures.

Another point to consider is the adaptability of rodless cylinder designs. Changing production environments? No problem! These cylinders can be customized easily. Yet, such flexibility requires thorough planning to ensure efficiency. Engage with your team to map out the integration process.

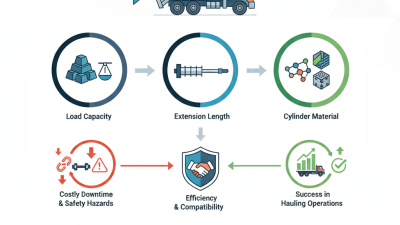

Rodless piston cylinders have gained traction across various industries due to their versatility. These components are pivotal in automating manufacturing processes. In fact, a recent report noted that nearly 40% of automations use pneumatic technology. Their adaptability spans sectors from automotive to food processing.

One striking advantage is their space-efficient design. Unlike traditional cylinders with protruding elements, rodless systems minimize footprint. This feature appeals to industries where space is at a premium. A survey highlighted that 70% of engineers seek compact solutions for modern machinery. However, not all applications benefit equally. Some specific tasks may still require traditional designs.

Furthermore, rodless cylinders provide smooth, linear motion, which is critical in assembly lines. This attribute enhances precision and reduces wear on components. A detailed analysis revealed that companies using these cylinders reported a 20% increase in operational efficiency. However, integration challenges can arise, making it essential to assess your setup. The choice isn't always straightforward, and potential users must carefully evaluate their needs.