+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

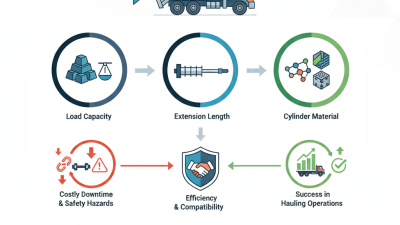

Choosing the right hydraulic oil cylinder is crucial for achieving maximum performance in various applications. These cylinders are essential components in hydraulic systems, enabling efficient power transfer. The market offers numerous options, each with unique features and specifications.

Selecting the best hydraulic oil cylinder requires careful consideration of specific needs. Factors such as load capacity, stroke length, and environmental conditions all play a key role. You may find yourself overwhelmed by the choices available. It's essential to align cylinder capabilities with your project requirements.

While many cylinders boast impressive performance, not all meet expectations. Some may fail under heavy loads or harsh conditions. Investing in quality is vital. It’s wise to review performance data and user feedback before making a decision. Understanding both the strengths and limitations of these hydraulic oil cylinders will lead to informed choices, enhancing overall efficiency and safety.

When choosing hydraulic oil cylinders, it’s essential to focus on key features that influence performance. One important factor is the cylinder bore size. A larger bore typically allows for higher hydraulic flow rates. This can significantly impact overall system efficiency. According to industry reports, proper sizing can improve energy consumption by up to 15%.

Another critical feature is the cylinder stroke length. It directly affects the range of movement and capability of the hydraulic system. A shorter stroke may limit performance in certain applications. Regular analysis suggests that adjusting stroke lengths can enhance operational flexibility. Make sure the cylinder matches your specific requirements.

Tip: Always consider the maximum operating pressure. This can affect safety and durability.

The choice of materials is also vital. Steel cylinders are more durable, but aluminum can reduce weight. Balancing these factors is crucial for performance and cost-effectiveness. It's a common oversight to choose based solely on price. Conducting thorough research and analysis can help in making the best decision.

Tip: Regular maintenance and inspections extend the life of your hydraulic cylinders. Proper care prevents costly repairs and enhances performance.

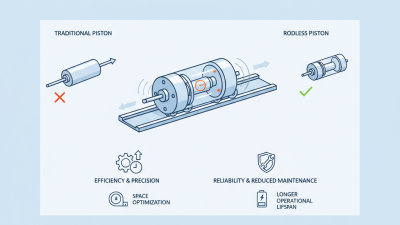

Hydraulic oil cylinders come in various types, each tailored for specific tasks. The most common types include

double-acting,

single-acting, and

telescopic cylinders.

Double-acting cylinders provide force in both directions, while single-acting cylinders work in one direction, utilizing gravity or spring return.

Telescopic cylinders allow for a compact design with extended reach, ideal for applications with space constraints.

Tips: When selecting a cylinder, consider the operating pressure and load requirements. Check your application’s constraints thoroughly. Understanding these details can lead to better performance.

Different applications demand specific features. For example, agricultural equipment often uses heavy-duty cylinders with robust seals. Construction machinery may require cylinders designed for high-speed operations. Each design choice has its unique merits and pitfalls. It’s essential to balance performance with the conditions the cylinder will face.

Tips: Periodically inspect cylinders for wear and leaks. Preventative maintenance can save costs over time. A well-maintained cylinder increases reliability and lifespan. Always assess if the chosen type truly meets your needs.

When it comes to hydraulic oil cylinders, performance matters. Many brands strive to deliver optimal solutions for various applications. These brands often focus on durability and efficiency, ensuring their products can withstand heavy use. Quality engineering leads to better performance, which can save time and resources.

High-performance hydraulic oil cylinders are engineered for specific needs. They often include advanced sealing systems to prevent leaks. The right materials can enhance longevity and reduce wear. Some designs allow for easy maintenance, a critical feature that shouldn’t be overlooked. Users sometimes underestimate the importance of regular inspections and timely upkeep. Neglect can lead to costly errors and unexpected downtimes.

Performance isn't just about the cylinder itself. It involves understanding how it fits into your overall system. Some users may not fully appreciate the impact of proper installation. Choosing a cylinder that suits your equipment is vital. If the wrong size or type is selected, it can lead to inefficiencies. Being aware of these details can aid in making better decisions for any project.

This chart represents the performance metrics of various hydraulic oil cylinders based on pressure capacity and cycle efficiency. The data showcases a comparative analysis of 10 different hydraulic oil cylinders.

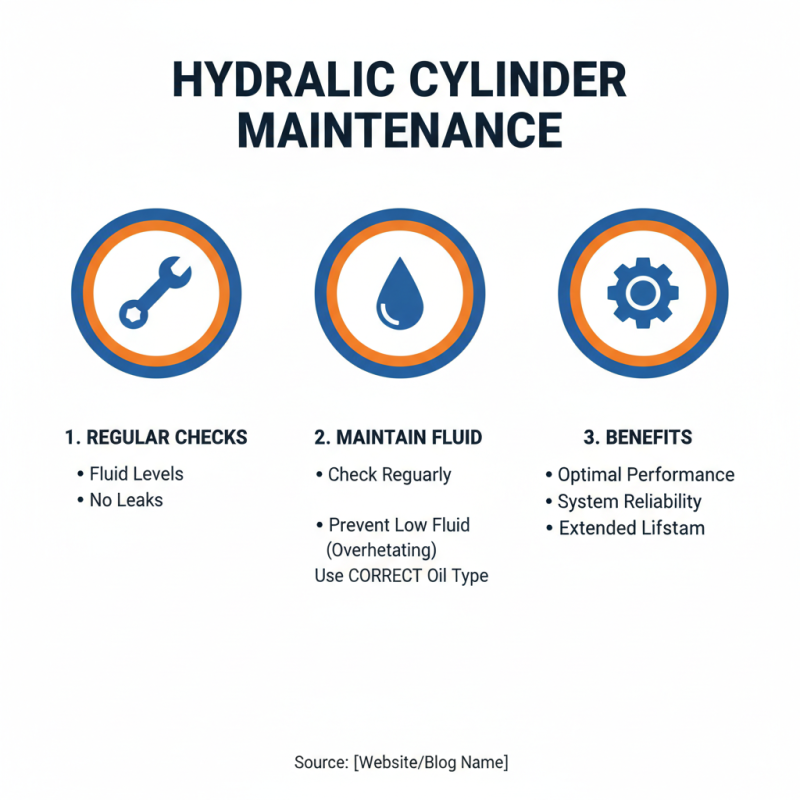

Hydraulic oil cylinders require regular maintenance for optimal performance. Checking the fluid levels is crucial. Low fluid can lead to overheating and system failures. It's essential to use the right type of hydraulic oil for your equipment. This prevents breakdowns and extends the life of the cylinders.

Inspecting seals and connections is another vital task. Worn seals can cause leaks. These leaks not only waste fluid but also reduce efficiency. Keeping the exterior clean helps in identifying leaks and damage early. Pay attention to any unusual noises during operation. It's a sign that something might be wrong.

Periodic flushing of the hydraulic system is often overlooked. Contaminants can build up over time, reducing the system's efficiency. However, not everyone remembers to do this. Learning to identify signs of wear can lead to better maintenance practices. Remember, even small issues can escalate if left unchecked. Focus on consistent care for your hydraulic cylinders to keep them in good condition.

Hydraulic oil cylinders are crucial for various industrial applications. Their performance significantly impacts project efficiency. A comparative analysis of pricing and quality reveals considerable variations in the market. Some studies show that high-quality cylinders can cost up to 30% more than standard alternatives. However, these high-end options often provide better durability and efficiency, leading to long-term savings.

Quality assessment in hydraulic cylinders often involves factors like cylinder material and seal design. Research indicates that cylinders made with high-grade steel show a 40% increase in lifespan compared to those made from lower-quality materials. Additionally, advanced seal designs enhance performance, reducing leaks and downtime. Yet, many buyers overlook these details, opting for cheaper models that may fail prematurely.

To achieve maximum performance, companies should weigh initial costs against potential risks. Investing in reliable hydraulic cylinders may seem daunting. However, the consequences of frequent replacements can outweigh upfront savings. As the industry evolves, understanding these dynamics becomes essential for informed purchasing decisions.

| Model | Bore Size (inches) | Stroke Length (inches) | Max Pressure (psi) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 2 | 10 | 3000 | 50 | 250 |

| Model B | 2.5 | 12 | 3500 | 60 | 300 |

| Model C | 3 | 14 | 4000 | 70 | 350 |

| Model D | 4 | 16 | 4500 | 80 | 400 |

| Model E | 5 | 18 | 5000 | 100 | 500 |

| Model F | 5.5 | 20 | 5500 | 120 | 600 |

| Model G | 6 | 22 | 6000 | 140 | 700 |

| Model H | 6.5 | 24 | 6500 | 160 | 800 |

| Model I | 7 | 26 | 7000 | 180 | 900 |

| Model J | 7.5 | 28 | 7500 | 200 | 1000 |