+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right Hydraulic Lift Cylinder is crucial for efficiency and safety in many industries. According to a recent report by the American Society of Mechanical Engineers, improper selection can lead to a 20% decrease in performance. This statistic highlights the importance of matching the cylinder to specific applications and load requirements.

Industry expert Dr. Emily Carter states, "Selecting the right Hydraulic Lift Cylinder can significantly impact operational efficiency." Her insights underline the need for careful evaluation of factors such as load capacity, bore size, and mounting type. Each project may have unique demands that cannot be overlooked.

In a market with numerous options, it is easy to feel overwhelmed. Mistakes in selection can result in costly downtime or even accidents. Understanding the core specifications of Hydraulic Lift Cylinders and their applications is vital for making informed choices. Taking time to assess needs and consult with specialists can help. The right choices can lead to improved productivity and safety.

Hydraulic lift cylinders play a critical role in various applications, including construction, manufacturing, and automotive services. These components convert hydraulic energy into mechanical force. They are vital for lifting heavy loads smoothly and efficiently. According to a report by Research and Markets, the global hydraulic cylinder market is projected to reach $20 billion by 2027. The demand for efficient lifting solutions drives this growth.

Selecting the right hydraulic lift cylinder requires understanding your specific needs. Load capacity, stroke length, and mounting style are key factors. For example, a cylinder that doesn’t meet the weight requirement can lead to breakdowns. Additionally, the wrong stroke length may lead to operational inefficiencies. It’s essential to assess the working environment as well. High temperatures or corrosive substances can impact cylinder performance.

Tips: Consider the hydraulic fluid type. Fluids not meeting viscosity requirements can damage seals. Always check compatibility with your system.

Not all cylinders are created equal. Sometimes, manufacturers promise quality that’s hard to deliver. Evaluate customer reviews and case studies to gauge actual performance. Take time to consult with experts when making your choice. This can prevent costly mistakes and ensure long-term reliability.

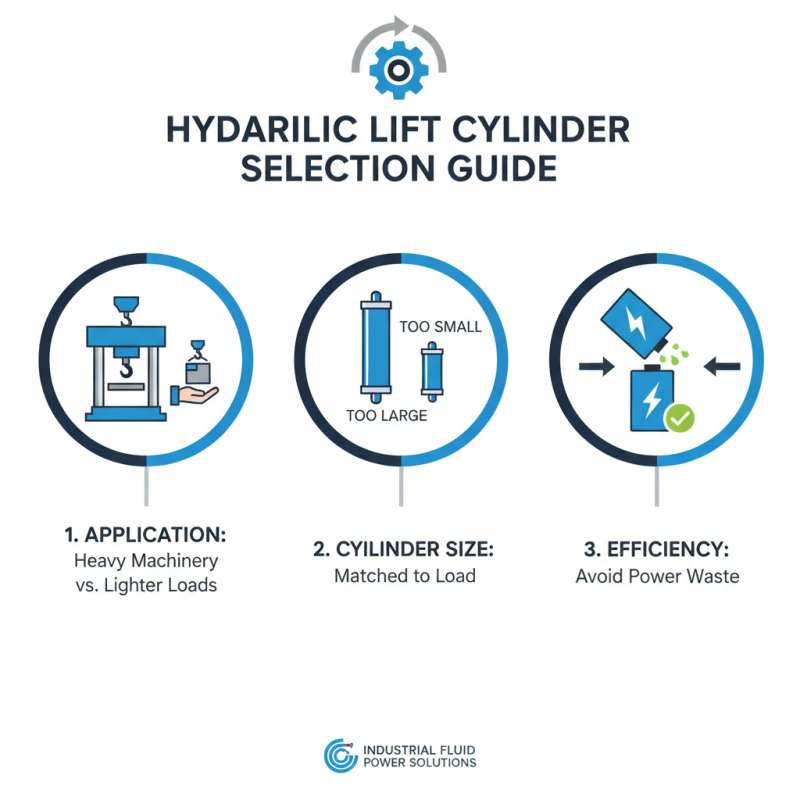

When choosing a hydraulic lift cylinder, several key factors come into play. The application is crucial. Are you lifting heavy machinery or lighter loads? Each application demands different specifications. The size of the cylinder matters too. A cylinder that's too small will struggle, while one too large may be overkill, wasting power.

Pressure ratings are another vital consideration. A cylinder must handle the pressure without failing. This requires knowing the maximum load during operation. Poor pressure choices lead to equipment failure. Understanding the environment is also essential. Will the cylinder face dust, moisture, or extreme temperatures? These conditions affect material choice and durability.

Tips: Always check the specifications. Look for details on stroke length and bore diameter. These determine how effectively the cylinder performs. Don't overlook mounting options. Proper mounting can prevent misalignment issues. If you're unsure, consult with a technician. They can provide insights tailored to your unique requirements. Remember, it's worth spending time on these decisions upfront to avoid problems later.

Choosing the right hydraulic lift cylinder involves careful consideration of

capacity and stroke length.

Capacity refers to the maximum weight the cylinder can lift. According to industry reports, standard capacities range

from 500 to 20,000 pounds. However, misuse often occurs.

Overloading a cylinder can lead to failure, posing safety risks. Assess your specific needs before selecting a capacity.

Stroke length is another critical factor. It determines how far the lift can extend. Common stroke lengths vary from

6 to 36 inches. Selection should align

with your application requirements. Misjudging stroke length often results in insufficient lift height.

Measure carefully. An incorrect size can hinder efficiency. Understand the operational needs clearly.

Proper sizing improves productivity and ensures safety.

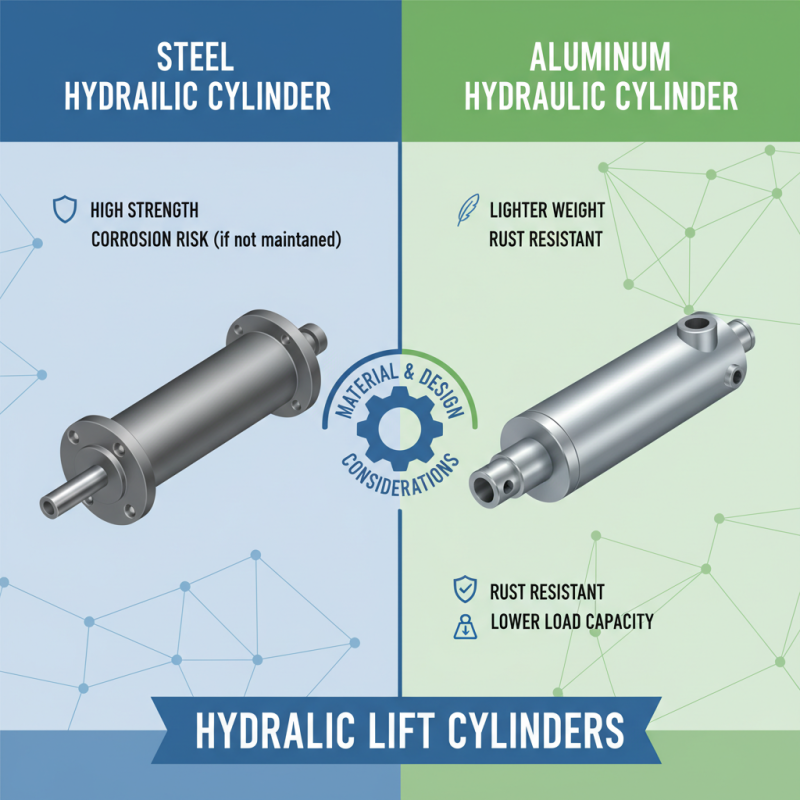

Choosing the right hydraulic lift cylinder involves significant material and design considerations. Different materials can affect durability and performance. For instance, steel offers high strength but may corrode if not properly maintained. Aluminum is lighter and resistant to rust, yet it may not handle heavy loads as effectively.

Design also plays a critical role. The cylinder's size and shape influence how it performs under pressure. A compact design might fit tight spaces but could sacrifice lifting power. Balancing these elements requires reflection and careful thought. Understanding the tasks the cylinder will perform is vital. It often leads to better selections, aligning with real-world needs. Exploring various options can reveal unexpected shortcuts or challenges.

Hydraulic lift cylinders require regular maintenance to ensure safety and efficiency. According to industry studies, nearly 30% of hydraulic system failures are due to lack of maintenance. This highlights the importance of a consistent upkeep schedule. Check the seals and hoses frequently. Inspect for leaks and wear, as even minor issues can lead to serious accidents.

Safety is paramount when working with hydraulic systems. OSHA has reported that improper use of hydraulic equipment contributes to many workplace injuries. Ensure operators are trained. Encourage the use of personal protective equipment. Regularly review safety procedures with your team. If you spot unusual vibrations or sounds, act quickly. They may indicate a deeper problem.

Data from the Hydraulic Institute suggests that maintenance could extend the life of a lift cylinder by 50%. Regularly replacing hydraulic fluid not only improves performance but also minimizes risks. Keep a log of maintenance activities to identify patterns or recurring issues. Assessing your hydraulic lift cylinder's state of health is vital, and no detail is too small.