+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In modern hydraulic systems, choosing the right components is crucial. One option that stands out is the Rod End Cylinder. These cylinders offer distinct advantages in various applications. Industry data indicates that Rod End Cylinders can enhance efficiency by up to 25%. Their design allows for optimized force application and better alignment.

The versatility of Rod End Cylinders makes them a preferred choice across industries. They are commonly used in sectors like automotive, aerospace, and construction. According to reports from the International Fluid Power Society, the global demand for hydraulic systems will reach $40 billion by 2025. This growth is tied to the reliability of components like the Rod End Cylinder.

Despite their benefits, one must assess their application carefully. The wrong choice can lead to inefficiencies and increased costs. Understanding the specific needs of your hydraulic system is vital. This ensures that the inclusion of Rod End Cylinders is a strategic decision rather than a mere trend. Balancing the advantages and potential pitfalls can lead to optimized performance in hydraulic applications.

Rod end cylinders are an excellent choice for hydraulic systems. They offer unique advantages that enhance various applications. These cylinders are versatile, making them suitable for different functions. Their compact design allows for installation in tight spaces. This is particularly valuable in machinery where every inch counts.

One key benefit is their efficient performance. These cylinders provide smooth operation with minimal friction. This leads to better energy use and reduces wear over time. In addition, rod end cylinders can handle high loads and pressures. This capability is critical for industries relying on hydraulic power.

Tips: Regular maintenance is essential. Check seals and fluid levels frequently. This ensures that your equipment runs smoothly. Keep an eye on performance changes. Any odd behavior could indicate a problem.

Another point worth noting is the ease of installation. Many users find the process straightforward. However, misalignment can lead to issues. Always double-check alignment during setup. It can save time and resources in the long run. An overlooked detail might lead to operational inefficiency.

| Benefit | Description | Application Area |

|---|---|---|

| Space Efficiency | Rod end cylinders have a compact design that saves space in hydraulic systems. | Tight installations like robotics, automotive assembly lines |

| High Load Capacity | These cylinders can handle significant loads, providing reliable performance. | Heavy machinery, construction equipment |

| Versatility | Suitable for various applications, including both linear and rotary motion. | Manufacturing, aerospace, and marine |

| Easy Installation | Designed for quick installation and maintenance, minimizing downtime. | Automated systems and maintenance environments |

| Durability | Manufactured from high-quality materials for long service life under tough conditions. | Industrial sectors with harsh environments |

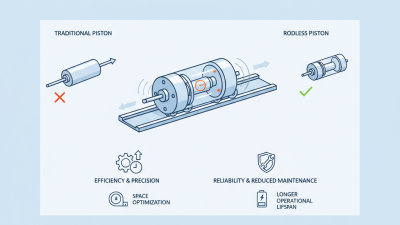

Rod end cylinders play a crucial role in hydraulic systems. Their unique design allows for efficient movement in various applications. Unlike traditional cylinders, they feature a rod end that connects directly to machines. This connection enhances precision and control, essential for complex tasks. Data from industry reports show that using rod end cylinders can improve efficiency by up to 30%.

The design of these cylinders includes a spherical bearing at the rod end. This feature enables multi-directional movement. It provides flexibility in orientation, which is vital in tight spaces. Many hydraulic systems require reliable motion under challenging conditions. Rod end cylinders can adapt easily to these demands. However, it’s essential to consider that the wear on the spherical bearing can impact performance over time.

Additionally, rod end cylinders are often more compact than other options. Their size can free up valuable space in installations. This factor is increasingly important in modern engineering, where every inch counts. Nevertheless, improper installation can lead to unforeseen problems, affecting the overall performance of the hydraulic system. Regular maintenance and checks can mitigate this risk. Yet, many overlook this crucial aspect.

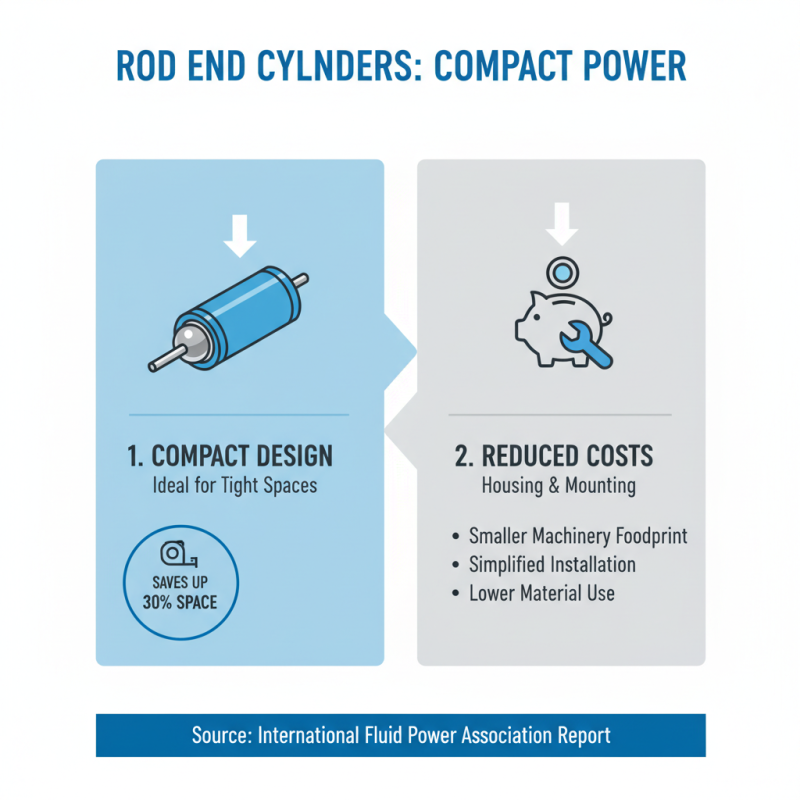

Rod end cylinders present unique advantages when compared to traditional cylinder types. These cylinders boast a compact design that is ideal for tight spaces. A report from the International Fluid Power Association indicates that rod end cylinders can save up to 30% more space than standard cylinders. This space efficiency can lead to reduced costs in housing and mounting.

However, it's crucial to consider the challenges these cylinders face. Their design can lead to faster wear in high-load applications. The increased movement range may compromise their stability under certain conditions. A study highlighted that approximately 15% of hydraulic failures are linked to improper rod end cylinder installation.

Additionally, rod end cylinders offer high versatility in motion control. The ability to pivot enhances their application across various industries. Yet, one should ponder if this flexibility results in complexities during maintenance. Regular inspection and timely adjustments can become essential for optimal performance. Balancing the advantages and potential drawbacks is vital for effective hydraulic system design.

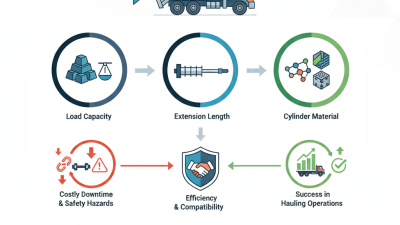

Rod end cylinders are crucial in various industries, enhancing hydraulic systems' efficiency and reliability. These cylinders are widely used in agriculture, automotive, and aerospace sectors. They offer flexibility and adaptability, making them ideal for applications requiring precise movements. For instance, in agriculture, rod end cylinders operate equipment like seeders and harvesters, ensuring accurate performance.

In automotive applications, they assist in steering and suspension systems. Their compact design allows them to fit into tight spaces while delivering robust force. Moreover, in aerospace, they facilitate the actuation of control surfaces, providing smooth operation under extreme conditions. Rod end cylinders' versatility helps optimize productivity across these industries.

**Tip:** Always consider the load requirements when selecting rod end cylinders to ensure optimal performance. The wrong choice can lead to system failures or inefficient operation.

Choosing the right material is also essential. Different environments may require diverse materials for durability. Stainless steel, for example, offers corrosion resistance in harsh conditions.

In every application, assessing the specific needs is crucial. Sometimes, less common configurations are necessary. Explore various designs before finalizing your choice. The right rod end cylinder can significantly impact efficiency and safety.

Rod end cylinders play a crucial role in hydraulic systems. Keeping them in optimal condition is essential for efficiency. Regular maintenance can prevent costly repairs and improve performance. Ensuring the rod end is free of dirt and debris is vital. A clean environment helps maintain smooth operation.

Regularly inspect seals for wear and tear. Damaged seals can lead to leaks, affecting system performance. Replace them promptly to avoid worse issues. Lubricate the joints with the appropriate grease. This reduces friction, enhancing longevity. However, over-lubrication can cause problems. Finding the right balance is important.

Check for any signs of rust or corrosion. Moisture can be detrimental. If rust is found, clean the affected areas immediately. A proactive approach can save time and resources. Monitor cylinder alignment as well. Misalignment can lead to uneven wear. Address any misalignment issues early to ensure smoother operation.