+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

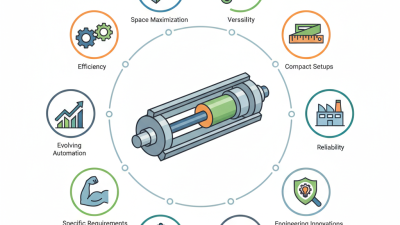

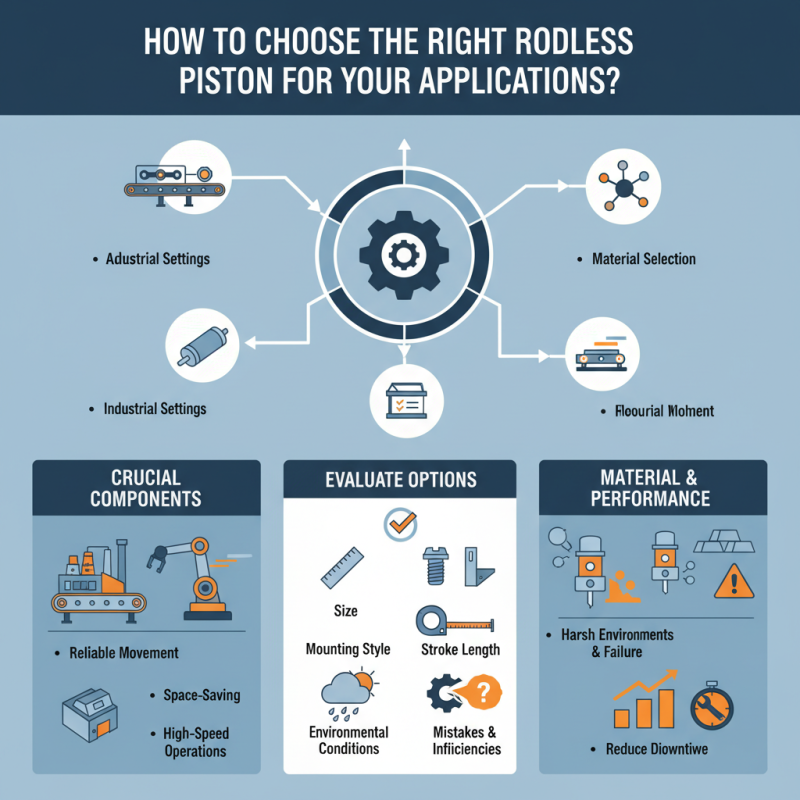

Choosing the right rodless piston can significantly impact your application’s efficiency and effectiveness. In industrial settings, these components are crucial. They offer reliable movement without the typical constraints of a traditional rod design. The unique features of rodless pistons cater to various needs, from space-saving applications to high-speed operations.

When evaluating options, consider the specific requirements of your project. The size, mounting style, and stroke length matter greatly. It’s easy to overlook details like environmental conditions. Sometimes, users mistakenly choose a model without understanding its limitations. This can lead to inefficiencies and costly mistakes.

Additionally, the material may also play a role in the decision-making process. A rodless piston made from the wrong material can fail prematurely in harsh environments. Therefore, evaluate your application carefully. Reflect on how these factors affect overall performance. A thoughtful choice can enhance productivity and reduce downtime.

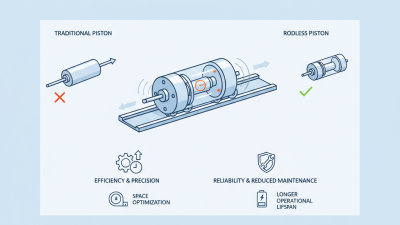

Rodless piston technology is gaining traction in automation and machinery applications. This innovative design eliminates the need for a traditional rod, offering a compact solution for linear motion. The piston moves within a sealed cylinder, which allows for greater flexibility in design. Its streamlined nature makes it easier to integrate into tight spaces.

When choosing a rodless piston, consider the specific needs of your application. Think about the load it needs to move and the required speed. It's crucial to assess the environment too. Harsh conditions or limited space can complicate your choice. Some may overlook these factors, leading to inefficient or faulty installations. Consulting with experts can provide clarity and prevent costly mistakes.

Moreover, potential issues may arise during operation. For instance, wear and tear can affect performance over time. Regular maintenance is essential for longevity. However, not everyone observes this need. Sometimes, users find themselves trapped in the cycle of reactive repairs. Addressing these challenges head-on can improve both performance and lifespan of the system.

When selecting a rodless piston for your applications, several key factors should guide your decision. One crucial aspect is the intended use. Think about the environment, load capacity, and speed requirements. Is it for a conveyor system or a robotic arm? Understanding the specific application can significantly influence your choice.

Tips: Consider the operating conditions. A rodless piston may need to withstand dust or moisture. Ensure it has appropriate seals for longer durability.

Another factor is the space limitations. A compact design is often essential in tight areas. Evaluate the dimensions of the installation site. Additionally, consider maintenance needs. Some models may require more frequent servicing than others.

Tips: Look for models with easy access to components. This feature can save time and reduce downtime.

Lastly, don’t overlook the importance of compatibility. Ensure that the rodless piston coordinates with existing equipment. Misalignment can lead to inefficiencies. Assess all these elements thoughtfully to choose wisely.

| Factor | Description | Importance Level |

|---|---|---|

| Stroke Length | The maximum distance the piston will travel. | High |

| Load Capacity | The maximum load the rodless piston can handle. | High |

| Speed | The operational speed of the piston during actuation. | Medium |

| Operating Environment | Conditions such as temperature, humidity, and exposure to chemicals. | High |

| Installation Space | Available space for the installation of the rodless piston. | Medium |

| Material | Material of the piston for durability and compatibility. | Medium |

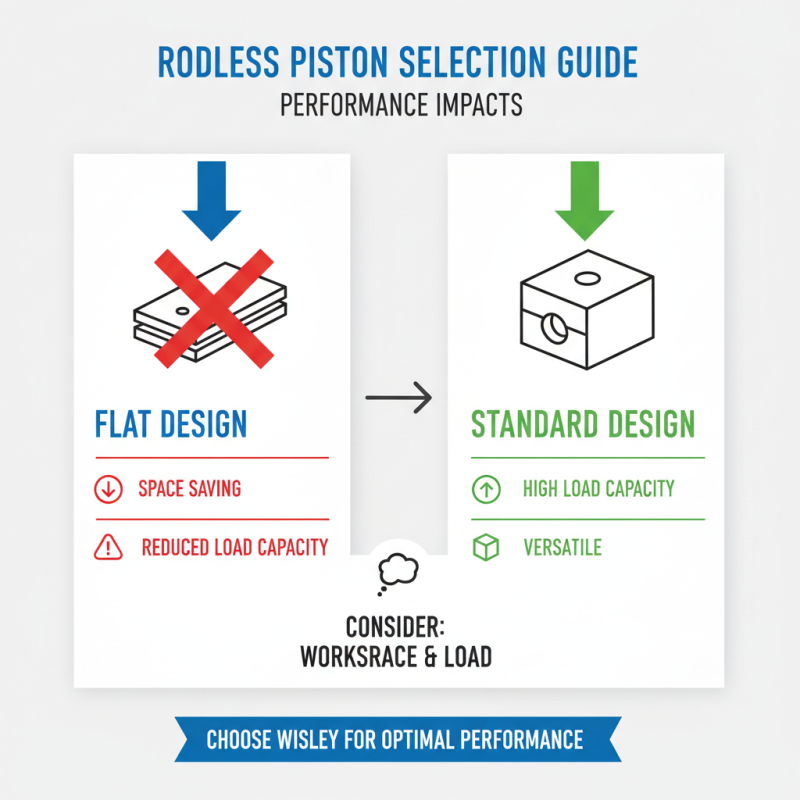

When choosing a rodless piston, the type can greatly impact performance. There are various configurations available. Each type has unique advantages and disadvantages. For example, a flat design can save space. However, it may have reduced load capacity. Consider your workspace and load requirements carefully.

Another type of rodless piston is the belt-driven version. This type allows for longer strokes. It can also handle heavier loads. But, it has a greater complexity. Maintenance might become an issue over time. If you opt for this type, prepare for potential challenges.

Lastly, pneumatic rodless pistons can provide smooth operation. They are often compact and efficient. Yet, they require a reliable air supply. Without it, overall performance can suffer. In reviewing these types, reflect on your specific application needs. A misstep here can lead to inefficiencies.

Choosing the right rodless piston involves assessing the performance and efficiency that your application demands. Understanding the load requirements is crucial. Heavier loads need more powerful pistons. However, don't overlook the effect of friction. A low-friction design can improve efficiency, even with lighter weights.

Next, think about speed. Some applications require rapid movement. Others need slow, precise actions. Selecting a piston that matches your speed needs is vital. Keep in mind the operating environment as well. Humidity and temperature can greatly influence performance. Ask yourself, will the piston hold up?

Lastly, consider energy consumption. Efficient designs can save costs in the long run. Sometimes, the most robust option isn't the most efficient. It’s about finding balance. Each application has unique needs. Testing different configurations may be necessary. Accept that perfection takes time.

This chart illustrates the efficiency percentage of various rodless pistons. Choosing the right rodless piston involves evaluating their performance, and this visual representation helps in understanding their comparative efficiency.

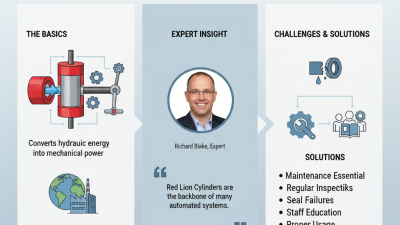

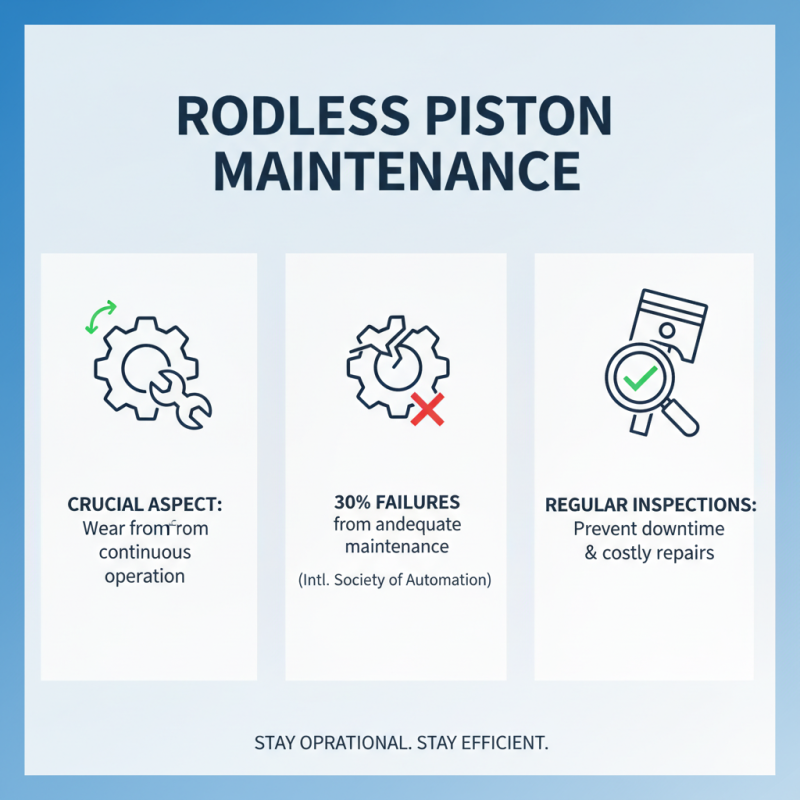

When selecting a rodless piston, maintenance is a crucial aspect. Rodless pistons often experience wear due to continual operation. According to a study by the International Society of Automation, 30% of pneumatic equipment failures arise from inadequate maintenance. Regular inspections can reveal early signs of wear, helping to avoid costly downtimes.

Lubrication is vital for maximizing longevity. A good lubrication schedule can enhance the lifespan by 25%. However, many operators overlook this aspect. They may think that enough oil is applied, but the reality can be quite different. Inadequate lubrication leads to increased friction, ultimately causing breakdowns.

Environment factors also play a role. Dust and contaminants can deteriorate performance. A clean workspace and proper filtration systems should be integral to your maintenance routine. Neglecting these can cut the lifespan of your rodless piston significantly. Often, companies prioritize productivity, but this can backfire if equipment fails due to poor upkeep. Investing time in maintenance is not just necessary; it is a strategic approach to operational efficiency.