+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Selecting the appropriate Slewing Ring for your project can be a challenging task. It involves various considerations that can impact your project's efficiency and performance. Understanding the specific requirements, such as load capacity and operational speed, is crucial.

Slewing Rings are essential components in many machinery applications. They allow for rotation and positioning, which is vital in industries like construction and robotics. However, not every Slewing Ring will fit your needs. There are many types available, each with unique specifications and uses.

Project managers often overlook important details during the selection process. This can lead to improper fit and functionality issues later. Effective communication with suppliers is key. Ask questions and be clear about your requirements. Reflect on prior experiences that highlight the significance of choosing the right Slewing Ring. A thoughtful approach can save time and resources in the long run.

Slewing rings are crucial components in various industries, enabling smooth rotation in machinery. Understanding the types and applications of slewing rings can significantly enhance project efficiency. There are several types, including gear-driven and friction-driven rings. Each type caters to different load requirements and rotational speeds.

In construction, slewing rings support cranes, allowing them to lift heavy materials with precision. According to a recent industry report, over 30% of machinery failures in construction relate to these components. Proper selection of the slewing ring can mitigate such issues.

**Tips:** Always assess the load capacity and rotational speed needed for your project. Consider environmental factors like temperature and dust exposure as they can affect performance.

In the renewable energy sector, slewing rings play a vital role in tracking solar panels. Their durability is tested against harsh conditions. Failing to choose the right type can result in costly downtime. Pay attention to specifications from manufacturers, yet remember they might not cover all scenarios. Adapting standards to specific project demands can provide better results.

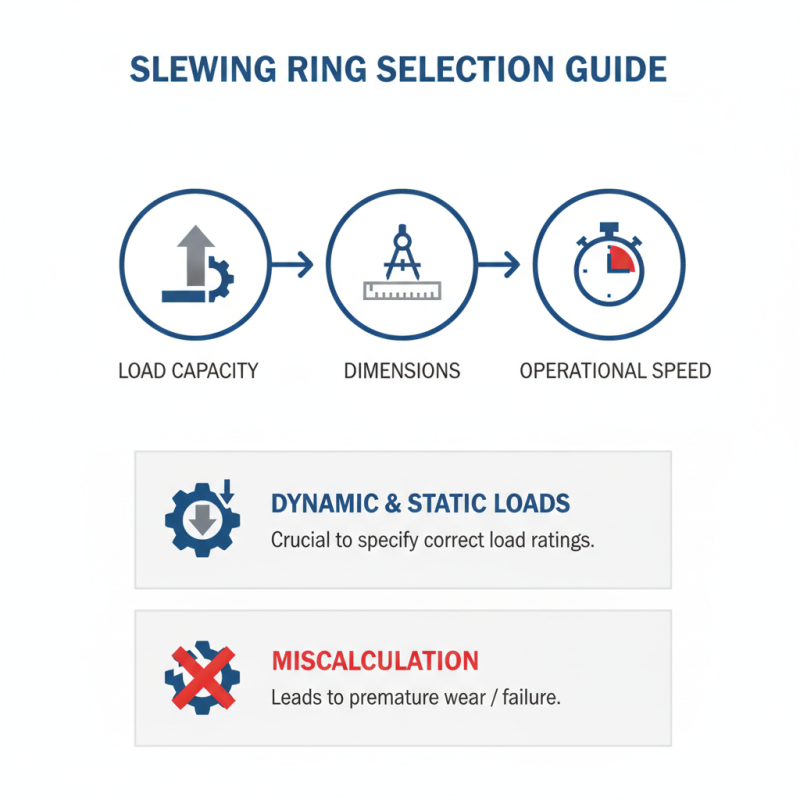

Choosing the right slewing ring for your project requires careful consideration of several key factors. These include load capacity, dimensions, and operational speed. According to recent industry reports, slewing rings must support significant dynamic and static loads. Hence, specifying the correct load ratings is crucial. Miscalculating load capacities can lead to premature wear or failure.

Material selection also plays a vital role. High-quality steel or specialized alloys offer better resistance to wear and fatigue. Different projects may require different material grades. For instance, a construction application might need corrosion-resistant materials. Failing to choose suitable materials may result in increased maintenance costs.

**Tips:** Always consult technical datasheets for load ratings. Understand your project's unique requirements. Regularly review performance indicators to gauge effectiveness. Skipping these steps can lead to costly mistakes down the line.

Another important aspect is the installation process. Proper alignment and torque settings are essential for optimal performance. A poorly installed slewing ring can create additional stress and lead to malfunctions. Always refer to guidelines to achieve the best results. Regular inspection and maintenance will also prolong the life of the assembly.

Choosing the right slewing ring involves careful consideration of material options. Steel is often the go-to choice. It offers great strength and durability. This makes it ideal for heavy-duty applications. However, steel can also be quite heavy and may require additional support structures.

Aluminum presents a lighter alternative. It’s easier to handle and often more cost-effective. However, it may not provide the same level of strength as steel. That means it’s best suited for lighter loads or applications where weight is a concern. The trade-off between strength and weight is crucial to consider.

Plastic slewing rings can be appealing due to their resistance to corrosion and chemicals. They operate quietly and are often shock-absorbent. Yet, they might not handle heavy loads as effectively as steel or aluminum. Evaluating each material’s properties helps make an informed decision. Ultimately, the right choice depends on the specific needs of the project. Consider testing different options to find the best fit. This is where some projects might stumble, as assumptions on material strength can lead to unexpected issues.

Choosing the right slewing ring for your project can feel overwhelming. One key aspect is calculating load capacity. This often requires attention to detail and understanding your project’s needs. A well-sized slewing ring can prevent mechanical failures. Knowing how to determine the right size is crucial for safety and efficiency.

Start by assessing the operational load. Consider both static and dynamic loads. It's essential to measure the weight of the components it will support. Calculate any additional load factors from movement or external forces. Avoid underestimating these requirements. Use specific formulas to find the necessary dimensions of your slewing ring.

**Tips:** Always consult engineering guidelines. They provide valuable formulas and insights into safety margins. Don’t rush this process. Reflect on your calculations, and double-check the figures. This attention can save you from costly mistakes later. Remember, if in doubt, seek expert advice.

This chart illustrates the load capacities of various slewing rings based on their diameter and rated load. Selecting the correct slewing ring is crucial for supporting the anticipated loads in any engineering project.

Slewing rings are vital components in various machinery. Proper maintenance significantly enhances their lifespan. Regular inspections can prevent unexpected failures. Lack of attention might lead to severe downtime. Ensure routine checks focus on lubrication and wear.

One useful tip is to keep slewing rings clean. Dirt and debris can cause friction. This can lead to overheating. Regularly cleaning the surfaces will greatly enhance their performance. Use appropriate cleaning agents that won’t damage materials. Avoid using harsh chemicals that could cause corrosion.

Another essential tip is to monitor operating conditions. Extreme temperatures can impact performance. Verify that the equipment operates within recommended limits. Incorrect settings can accelerate wear. Document every maintenance session to track performance trends. This can help identify potential issues early.