+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the world of hydraulic machinery, maintenance is crucial for ensuring reliability and efficiency. Dr. Emily Chen, a recognized expert in hydraulic systems, once said, "Regular upkeep of a Hydraulic Oil Cylinder is vital for optimal performance." This insight underscores the importance of diligent care and monitoring.

Hydraulic Oil Cylinders are essential components in many industries. They convert hydraulic energy into mechanical power. When these cylinders are not maintained properly, it can lead to leaks and inefficiencies. A simple inspection can reveal signs of wear, such as scratches or corrosion.

Neglecting these checks might seem harmless at first, but the long-term impacts are significant. A small leak can escalate into a major problem, affecting overall productivity. By prioritizing maintenance, users can enhance the lifespan and reliability of their Hydraulic Oil Cylinders, ensuring smooth operation in demanding environments.

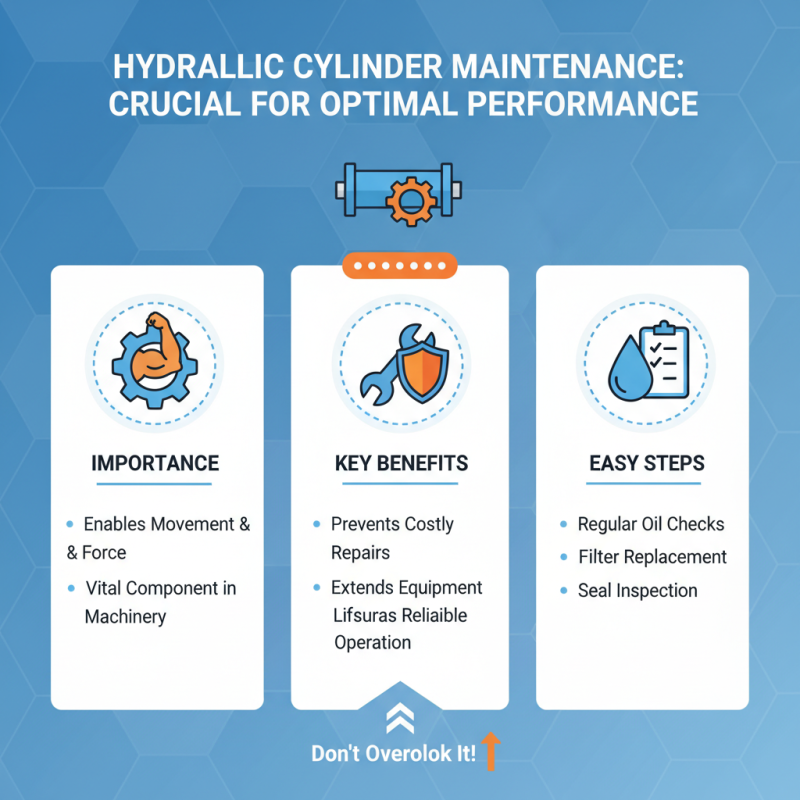

Maintaining a hydraulic oil cylinder is often overlooked, yet it is crucial for optimal performance. Hydraulic oil cylinders are vital components in various machinery. They enable movement and application of force. Regular maintenance can prevent costly repairs and extend the lifespan of the equipment.

Understanding the importance of maintenance means acknowledging common pitfalls. Many users forget to check oil levels regularly. Low oil can lead to overheating and premature wear. Additionally, contamination by dirt or water can cause significant issues. Keeping seals clean is essential, as dirt can cause leaks and impair function.

Starting a maintenance routine is a good idea. Regularly inspect for leaks and wear. It takes only a few minutes but can save you from bigger problems. Remember, small issues can escalate quickly if ignored. A proactive approach ensures your hydraulic oil cylinder operates efficiently. Neglecting basic care might lead to unexpected downtime. This reflects poorly on both the equipment and its operator.

Hydraulic oil cylinders are vital components in many machinery applications. Identifying common issues can prevent costly repairs. One frequent problem is fluid leakage. Check for oily residue around seals and connections. This can indicate wear or damage. If leaks are ignored, they worsen over time.

Another issue is contamination. Dirt and debris can enter the cylinder, causing wear and tear. Regular inspection of filters is crucial. Using a clean environment during maintenance helps. Moisture can also compromise the oil quality. Keeping the hydraulic system dry reduces corrosion risks.

Watch for unusual noises during operation. Grinding or hissing sounds may signal internal problems. If these arise, immediate investigation is necessary. Do not overlook any changes in performance either. Jerky movements may indicate issues with the cylinder's internal components. Regular attention to these details ensures safety and efficiency.

Regular inspection is vital for maintaining hydraulic oil cylinders. Start by checking for any visible leaks. Look closely at the seals and hoses. Even a small drop can indicate a problem. Next, examine the cylinder's exterior for signs of wear or rust. These issues can lead to bigger problems if not addressed quickly.

Cleaning is equally important. Use a soft cloth to wipe away dirt and grime. Pay special attention to the rod and the piston area. Dust and debris can damage seals over time. However, be cautious not to use harsh chemicals. They might degrade the materials instead of helping them. Sometimes, a gentle touch is all that’s needed.

Reflect on your routine. Are you consistent with these inspections and cleanings? It’s easy to overlook maintenance when everything seems to work well. Yet, ignoring minor issues can lead to costly repairs down the line. Keeping a maintenance log can help you stay organized. Regularly scheduled checks are the key to optimal performance.

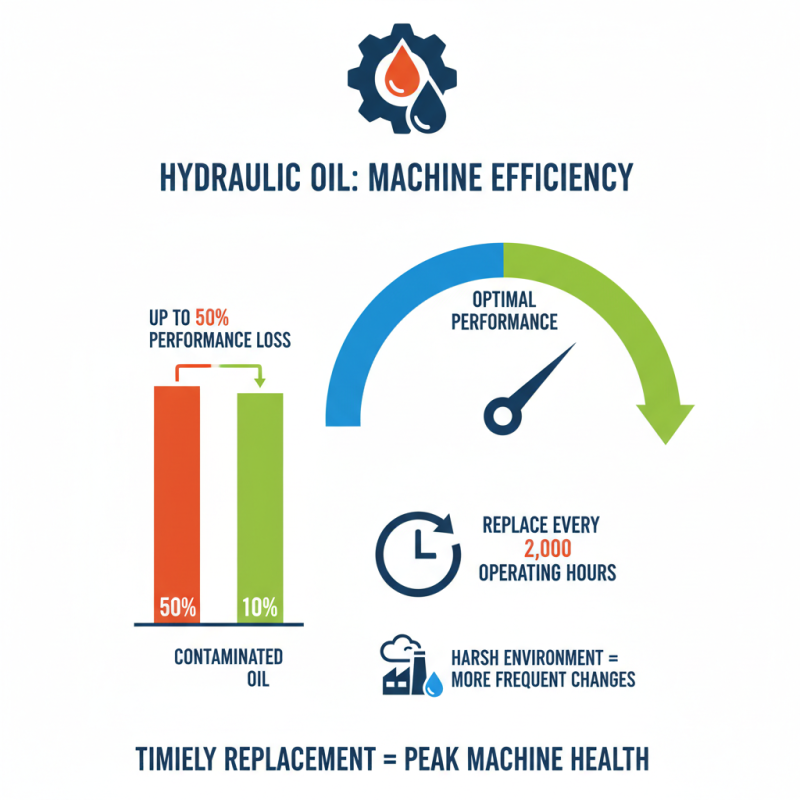

Hydraulic oil plays a crucial role in machine performance. Regular fluid replacement is essential to maintaining this efficiency. Studies show that contaminated oil can degrade system performance by up to 50%. This is why timely changes, ideally every 2,000 hours of operation, are vital. Depending on the environment, more frequent changes may be necessary.

Filtration is equally important. It helps remove particulates that can cause wear and tear. A report by industry professionals indicated that proper filtration could extend oil life by 25%. Selecting the right filter is important. Not all filters are created equal. Users should consider factors like particle size and saturation levels to ensure optimal filtration.

Improper maintenance can have significant repercussions. Some operators overlook fluid levels and quality, leading to catastrophic failures. Issues like aeration and foaming result from neglecting these basic practices. Regular checks on fluid quality can save costs in the long run. It's essential to encourage a culture of consistent maintenance and a keen eye for potential issues.

Proper storage and handling of hydraulic oil cylinders is crucial for their longevity and performance. Always place the cylinders in a clean, dry area. Dust and moisture can cause contamination. It's important to keep them upright when stored. This prevents oil leakage and maintains their integrity. Ensure they are not exposed to extreme temperatures or direct sunlight. Both can degrade the cylinder materials over time.

When handling these cylinders, wear appropriate safety gear. Accidental spills can be hazardous. Always use correct lifting techniques to avoid injuries. Inspect each cylinder for signs of wear or damage before use. This simple step can save time and resources. If a cylinder seems off, take the time to evaluate it. Skipping this step could lead to bigger issues down the line. Make it a habit to clean the threads and fittings before storage to ensure a good seal later on. Consider creating a checklist for regular maintenance and handling practices. This small effort can lead to improved efficiency and performance in the long run.