+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

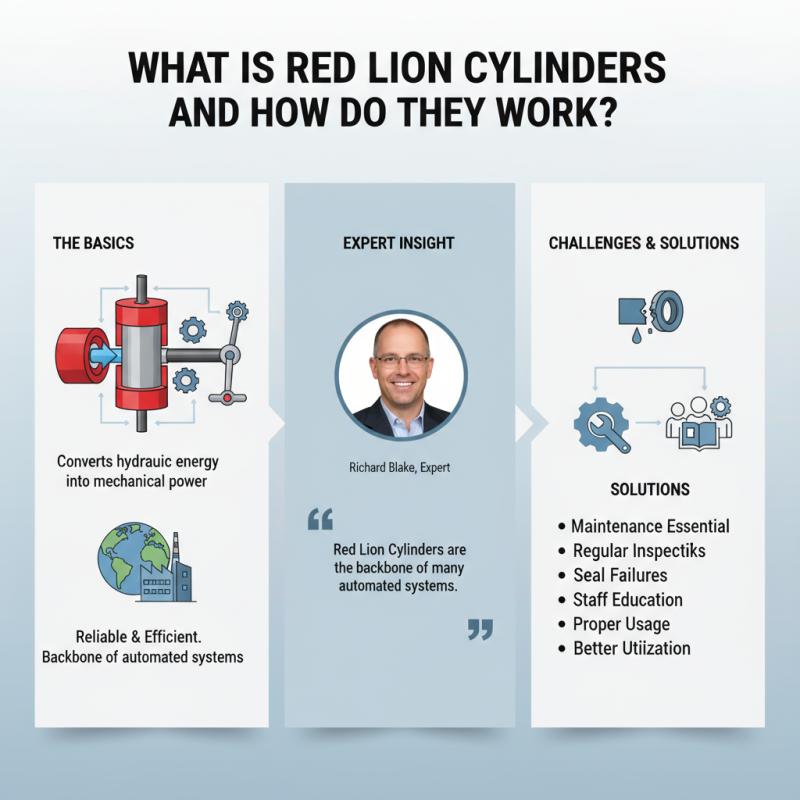

In the world of industrial machinery, Red Lion Cylinders play a crucial role. These hydraulic cylinders are known for their reliability and efficiency. According to expert Richard Blake, “Red Lion Cylinders are the backbone of many automated systems.” His insight reflects the importance of these cylinders in various applications.

Red Lion Cylinders are designed to convert hydraulic energy into mechanical power. They operate through a simple mechanism. When pressured fluid enters the cylinder, it pushes the piston. This action generates movement that drives equipment. It's fascinating how such a compact design can produce significant force.

However, challenges exist. Maintenance is essential for longevity. Hydraulic leaks and seal failures can cause issues. Many users overlook the importance of regular inspections. Educating staff about proper usage is also critical. The more we understand Red Lion Cylinders, the better we can utilize them.

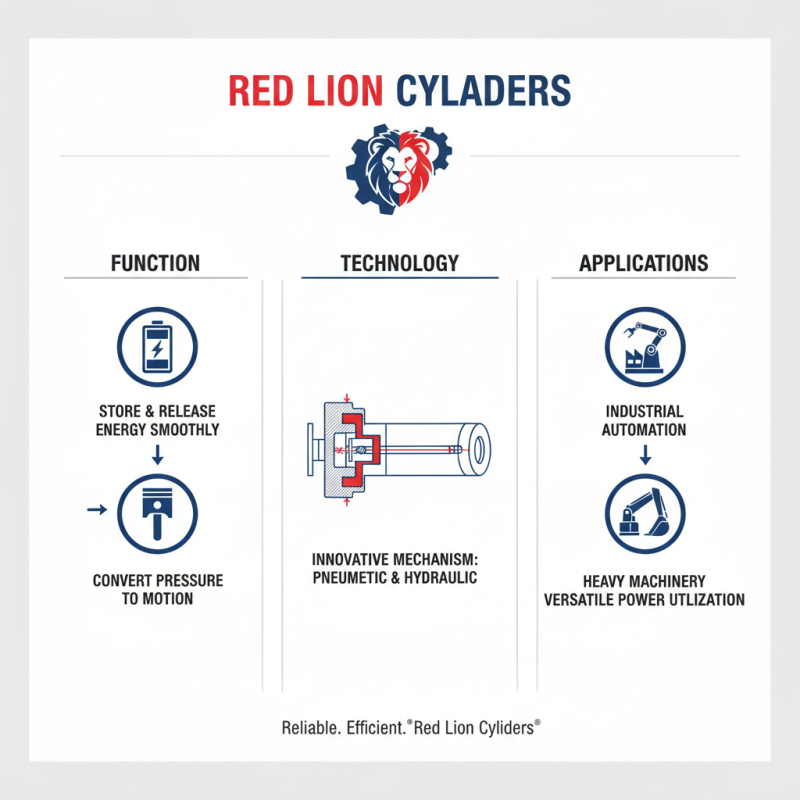

Red Lion Cylinders are fascinating devices widely used in industrial applications. These specially designed cylinders help store and release energy smoothly. Their innovative mechanism allows them to convert pressure into motion effectively. Users can harness this power for various pneumatic and hydraulic applications.

These cylinders consist of a robust body, seals, and moving components. The materials used are often lightweight yet durable, providing longevity. Each component plays a vital role in the cylinder’s function. However, improper maintenance can lead to reduced efficiency. Routine checks can be easily overlooked, which may result in unexpected downtime.

The mechanism of Red Lion Cylinders is fairly straightforward. When compressed air enters, it pushes against a piston, creating movement. This movement can then drive other machinery or tools. Understanding the environmental conditions is crucial. Overheating or contamination can compromise performance. Regular training for operators is essential to promote safe and effective usage.

Red Lion Cylinders find applications in diverse industries, particularly in manufacturing and automation. These cylinders excel in tasks requiring precise control and reliable performance. For instance, they play a crucial role in assembly lines, where they assist in picking, placing, and adjusting items. The control mechanisms allow for rapid and accurate responses, making processes more efficient.

In agriculture, Red Lion Cylinders serve essential functions in equipment like seeders and harvesters. They help regulate seed planting depth and optimize crop yield. In the automotive industry, these cylinders are invaluable for testing vehicle systems and components. Their adaptability makes them suitable for various conditions and requirements.

However, challenges exist. Maintenance can be demanding, and improper calibration can lead to inefficiencies. Users may struggle with integrating these cylinders into existing systems. It’s essential to evaluate the specific needs of each application and adapt the technology accordingly. Misalignment in settings might cause disruptions, emphasizing the need for careful planning and adjustments.

Red Lion cylinders are fascinating tools in mechanical systems. They are designed to convert energy into motion. These cylinders work on principles of compression and expansion. When compressed, they store energy. When released, they provide a powerful thrust. Their design allows for various settings, accommodating diverse applications.

These cylinders function using a simple mechanism. Inside the cylinder, a piston moves back and forth. As the piston moves, it changes the volume of gas or liquid inside. This change generates pressure, which propels the motion. Operators can adjust the input pressure for different outcomes. However, achieving optimal performance can sometimes be tricky. Small adjustments may lead to significant changes in efficiency.

Nevertheless, there are challenges. Misalignment can hinder their operation. Regular maintenance is crucial for longevity. If overlooked, efficiency drops. Additionally, excessive pressure can lead to failure. Users must remain vigilant and make periodic assessments. Engaging with these cylinders can be rewarding, but it demands attention and care.

Red Lion Cylinders are essential in various mechanical systems. These devices function as actuators, converting energy into linear motion. Their design aims for efficiency, often utilizing hydraulic or pneumatic force. This conversion allows for precise control in manufacturing processes, robotics, and automation. However, they can be bulky and require regular maintenance to ensure optimal performance.

Using Red Lion Cylinders brings several benefits. They provide reliable and consistent motion, enhancing productivity and accuracy. The ability to handle heavy loads makes them suitable for demanding applications. Additionally, they often have adjustable stroke lengths, allowing for versatility in different settings. Yet, high initial costs may deter some users. It's worth considering the long-term savings from increased efficiency. Regular checks and adjustments are also necessary to avoid issues like wear and tear. Balancing costs and benefits is critical for any project.

| Feature | Description | Benefits |

|---|---|---|

| Type | Hydraulic Cylinder | Provides powerful linear motion |

| Operating Pressure | Up to 3000 PSI | Efficient operation in demanding environments |

| Material | Aluminum Alloy | Lightweight and corrosion-resistant |

| Stroke Length | Varies (e.g., 1 to 10 ft) | Customization for specific applications |

| Mounting Style | Various options (e.g., flange, foot) | Adaptable to different systems |

Proper maintenance is crucial for the optimal performance of Red Lion cylinders. Regular inspections can help identify wear and tear. Check the seals and connections frequently. Ensure there are no signs of leaks. A small leak can lead to bigger problems later on.

Clean your cylinders to maintain functionality. Use a damp cloth to wipe the exterior. Avoid harsh chemicals that can damage the surface. It's easy to neglect this step but essential for longevity. Remember to store your cylinders in a dry place. Moisture can lead to corrosion over time.

Tips: Always check the pressure levels. This simple task can save you from unexpected issues. Document your maintenance schedule to keep track. Regular care is less time-consuming than big repairs later. Stay proactive and keep your equipment in good shape.