+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the realm of automation systems, the quest for efficiency and precision has led to the development of innovative technologies, one of which is the Rodless Piston. This sophisticated mechanism plays a crucial role in facilitating linear motion while eliminating the need for external rods, thereby enhancing design flexibility and space optimization. Unlike traditional piston systems that rely on rods to perform movements, the Rodless Piston operates through a unique sliding mechanism that allows it to move seamlessly along a predetermined track.

The advantages of integrating Rodless Pistons into automation systems extend beyond just space-saving capabilities; they also offer improved reliability and reduced maintenance requirements. With fewer mechanical parts at play, the likelihood of wear and tear diminishes, ensuring a longer operational lifespan. In various applications ranging from assembly lines to packaging, Rodless Pistons contribute to heightened productivity and streamlined workflows, making them essential components in modern engineering solutions. As industries continue to embrace automation, understanding the functionality and benefits of the Rodless Piston becomes increasingly pertinent for engineers and designers alike.

A rodless piston is a type of actuator widely used in automation systems for linear motion applications. Unlike traditional pistons that operate with a rod extending from a cylinder, rodless pistons feature an internal mechanism that allows for linear movement without the need for an external rod. This design results in a compact and streamlined profile, making them suitable for applications where space is limited.

Rodless pistons can be found in various systems, from conveyor belts to robotics, where precision and reliability are crucial.

The operation of a rodless piston involves the movement of a driving element within a sealed chamber. When air or hydraulic fluid is introduced, it generates pressure that drives the piston along the length of the cylinder. The unique design of the rodless piston allows for both pushing and pulling forces, providing versatility in mechanical systems. As the piston moves, it can easily accommodate changes in direction, increasing the efficiency of automation processes. This functionality, combined with the absence of an external rod, enables smoother motion and reduces wear on mechanical components in demanding environments.

Rodless pistons are innovative components used in automation systems that leverage pneumatic or hydraulic principles for movement without the need for a traditional rod. The principle of operation revolves around the use of a sealed cylindrical chamber, where pressurized fluid creates a force that drives a piston within. This design eliminates the external rod, allowing for compact and versatile installations that can operate in constrained spaces, making them ideal for various applications in automated processes.

In automation systems, the rodless piston operates through a straightforward mechanism of generating linear motion. When fluid enters the chamber, it pushes the piston, which is often connected to a movable carriage or load. As the piston moves, it can pull or push parts of the system, facilitating tasks such as picking, placing, or transporting items along a linear path. Notably, the absence of a rod minimizes friction and wear typically associated with traditional linear actuators, enhancing the efficiency and lifespan of the automation system. This cutting-edge technology significantly contributes to improved performance and reliability in industrial automation settings.

Rodless pistons have gained significant attention in automation systems due to their unique design and numerous advantages. Unlike traditional pistons that rely on a rod to transmit force, rodless pistons operate without this additional component. This design results in a more compact and lightweight system, allowing for greater flexibility in application setups. The linear motion achieved through rodless technology is efficient, making it particularly suitable for environments with limited space.

One of the primary advantages of using rodless pistons in automation is their ability to reduce friction and wear. The elimination of a rod means fewer moving parts, which not only lowers maintenance costs but also enhances the overall reliability of the system. Additionally, rodless pistons can achieve higher speeds and improved accuracy in applications ranging from material handling to assembly processes. This efficiency often leads to increased productivity in manufacturing environments, where speed and precision are crucial. Furthermore, their adaptability allows for easy integration into existing automation systems, providing manufacturers with a cost-effective solution for modernizing their operations.

Rodless pistons are increasingly being utilized in various industrial applications, primarily due to their compact design and efficient operation. One of the most significant advantages of rodless pistons is their ability to provide linear motion without the need for an external rod. This is particularly beneficial in environments where space is limited or where a traditional rod could hinder functionality. Their unique design allows them to deliver powerful movement while maintaining a low profile, making them ideal for applications such as automation systems in assembly lines, packaging machinery, and material handling.

In the realm of automation, rodless pistons can be employed in scenarios requiring precise positioning and smooth operation. For example, they can facilitate the movement of carousels in sorting systems or be integrated into robotic arms that require flexibility and precision. Additionally, industries such as food processing, pharmaceuticals, and electronics benefit from rodless pistons due to their ability to operate in clean, sanitary conditions while ensuring reliability. The adaptability of rodless pistons makes them a versatile choice for tackling diverse challenges across various sectors, enhancing efficiency and productivity in modern industrial environments.

| Application Area | Description | Benefits |

|---|---|---|

| Packaging Industry | Used for the movement of packaging materials and containers. | Improved efficiency in packaging lines with reduced footprint. |

| Automotive Manufacturing | Facilitates robotic arms for assembling and handling parts. | Increases precision and reduces cycle time. |

| Material Handling | Handles delicate materials without damaging them. | Enhances safety and minimizes waste during handling. |

| Textile Industry | Moves fabric and materials through various processes. | Streamlines production flow and reduces manual handling. |

| Semiconductor Manufacturing | Utilized in wafer handling systems to ensure precise movements. | Maintains clean environments and improves accuracy. |

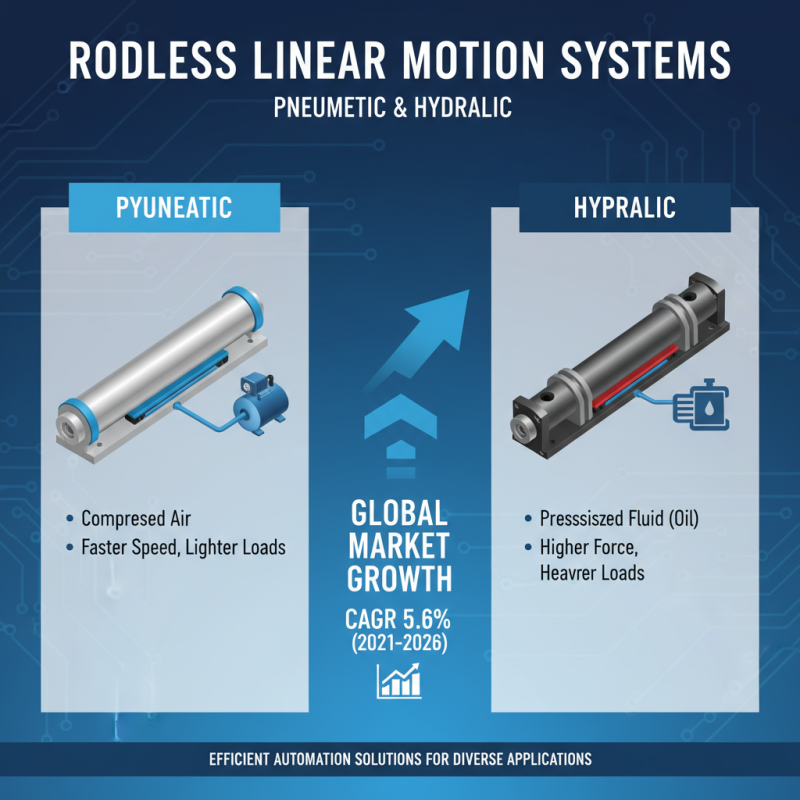

Rodless pneumatic and hydraulic systems are integral to modern automation, providing efficient solutions for linear motion applications. Both systems serve the same fundamental purpose, but they differ significantly in their mechanisms and applications. According to a report by the International Society of Automation, the global market for rodless actuators is expected to experience a compound annual growth rate (CAGR) of approximately 5.6% from 2021 to 2026, highlighting the increasing adoption of these technologies in various sectors.

Pneumatic rodless systems utilize compressed air to drive a piston without the need for a traditional rod. This design allows for compact installations and reduced maintenance, as there are fewer moving parts exposed to wear. They excel in applications requiring high-speed operations and responsiveness, making them ideal for assembly line work and packaging processes. Conversely, hydraulic rodless systems leverage pressurized fluid, providing greater force and better energy efficiency in heavier applications. Research indicates that businesses utilizing hydraulic systems can achieve energy savings of up to 30% compared to traditional systems, showcasing their effectiveness in demanding environments.

When comparing both systems, the choice often depends on the specific requirements of the application. Pneumatic systems are favored for their speed and simplicity, while hydraulic systems are preferred for their power and precision. A comprehensive analysis by the Motion Control Association indicates that industries such as automotive and packaging predominantly rely on pneumatic systems, whereas manufacturing and material handling sectors gravitate towards hydraulic solutions for their robustness.