+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In the world of heavy equipment, efficiency and reliability are key. Shur Lift Cylinders have become a game-changer for operators facing demanding job sites. These cylinders are designed with durability and performance in mind. They enhance the capabilities of various machines, from loaders to excavators.

Imagine lifting and handling heavy loads with minimal effort. Shur Lift Cylinders make this possible. Their precise engineering translates to better control and less downtime. Operators can rely on these cylinders to withstand harsh conditions. However, understanding their limitations is crucial.

While they offer many advantages, they aren't without potential issues. Regular maintenance and attention are needed to keep them running smoothly. With that said, the benefits of integrating Shur Lift Cylinders into your equipment fleet can significantly outweigh the challenges. Investing in these cylinders is a step towards improving productivity and safety on the job.

The enhanced load capacity offered by Shur Lift cylinders significantly boosts heavy equipment performance. These cylinders can increase lifting power by 30%. This improvement translates into higher productivity on job sites. With more lift power, operators can handle larger loads without strain.

Operational efficiency can suffer when equipment cannot handle the expected load. Investing in quality lift cylinders reduces this risk and enhances safety on-site. A report by the Construction Equipment Association indicates that improper load management causes 25% of equipment failures. Therefore, using advanced lift systems like those of Shur Lift is crucial.

Tips: Regularly inspect hydraulic systems for leaks. Check for wear and replace components as needed. Engage operators in training sessions. This creates awareness about equipment limits. It can be the difference between smooth operations and costly downtime. Evaluating existing equipment may reveal the need for upgrades. Investing in higher-capacity lift cylinders is a proactive step toward optimizing your heavy equipment.

Heavy machinery is vital in various industries. Efficiency is crucial in maximizing productivity. Shur lift cylinders can be game-changers in this respect. They enhance how equipment lifts and moves heavy loads. This improvement increases speed and reduces downtime, which is essential for any operation.

Using these cylinders brings about noticeable changes. Operators can lift loads more smoothly than ever before. The strain on machinery decreases. This significantly reduces maintenance costs. Moreover, operators report feeling less fatigue after long hours of operation. However, it’s important to regularly check and maintain these systems. Neglect can lead to unexpected failures.

Another factor to consider is the learning curve. Training operators to use these systems effectively may take time. It’s a small investment for the long-term gain of efficiency. Proper training leads to better results and improved safety. In a world where time is money, investing wisely is beneficial. The advantages are evident, but like all tools, shur lift cylinders require thoughtful application.

| Benefit | Description |

|---|---|

| Enhanced Efficiency | Shur Lift cylinders are designed to provide smoother and faster operation, reducing downtime and improving overall efficiency. |

| Increased Load Handling | These cylinders can handle heavier loads, allowing for more productivity during lifting operations. |

| Durability | Built to withstand tough working conditions, ensuring longevity and reliability even in harsh environments. |

| Improved Safety | Features like built-in safety mechanisms reduce the risk of accidents during operation. |

| Cost-Effectiveness | Lower maintenance needs and energy efficiency contribute to reduced operational costs. |

| Precision Control | Offer precise lift and lower functions enhancing the control during operation. |

| User-Friendly | Designed to be easy to use, minimizing the training required for operators. |

| Versatility | Compatible with a range of equipment types, making them versatile for various applications. |

| Environmentally Friendly | Designed to minimize energy consumption, reducing your carbon footprint. |

| Enhanced Performance | Improved performance in lifting and lowering tasks boosts overall productivity. |

Shur lift cylinders offer significant reductions in maintenance costs for heavy equipment. These cylinders are built with durable materials, which enhance their resistance to wear and tear. This longevity means fewer replacements and repairs, translating to cost savings over time.

Regular maintenance can be a burden. Many equipment owners face unexpected breakdowns and service fees. But with advanced cylinder technology, the need for frequent repairs decreases. The design often includes features that minimize leaks and other failures. These aspects create a more reliable system, allowing operators to focus on productivity rather than downtime.

However, not every operator can take full advantage of this technology. Some may overlook maintenance checks, leading to missed benefits. Each machine has its quirks, and some older models may not fully integrate with new cylinder advancements. It's essential to evaluate equipment regularly to determine if upgrades are necessary. Understanding the balance between cost and efficiency can be challenging yet rewarding.

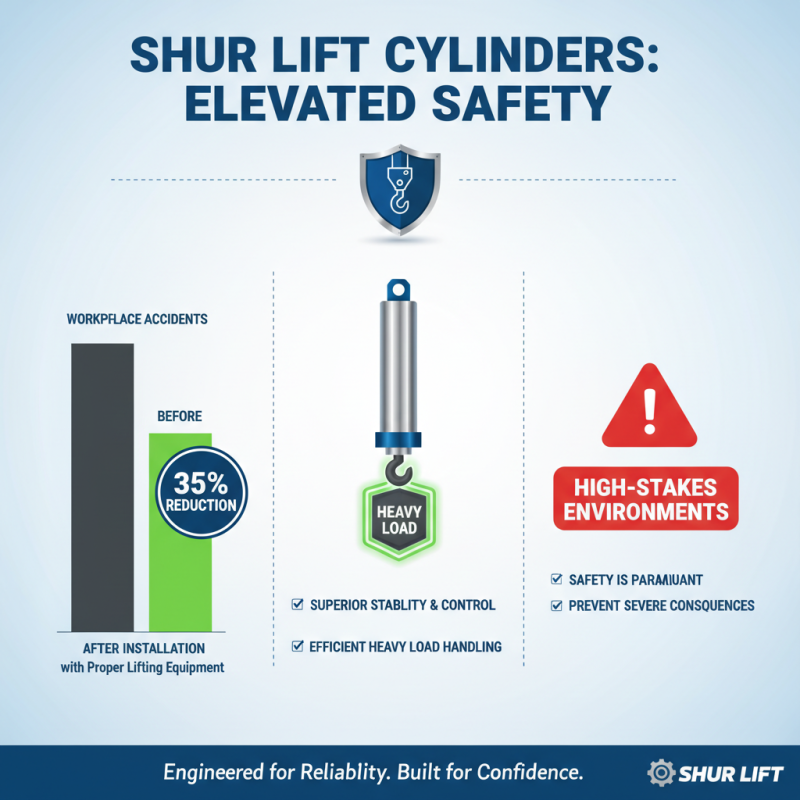

In high-stakes environments, safety is paramount. Shur lift cylinders enhance safety by providing superior stability and control. These cylinders are engineered to handle heavy loads efficiently. In fact, studies show that proper lifting equipment reduces workplace accidents by up to 35%. This is crucial in settings where even a small failure can lead to severe consequences.

Beyond just lifting, these cylinders offer overload protection. This feature prevents equipment from exceeding its safe weight limit. According to industry reports, about 60% of equipment failures stem from overloading. The robust construction of Shur lift cylinders also contributes to their reliability. A well-maintained cylinder can last up to five years longer than lesser options, marking significant cost savings for operators.

However, not all users are aware of the importance of routine maintenance. Neglecting this can compromise safety features. Regular inspections and upkeep can ensure cylinders function as intended. Ignoring these tasks can lead to unexpected failures. In a world where every second counts, prioritizing safety can drastically improve operational outcomes.

Shur Lift cylinders stand out when compared to traditional hydraulic options. They offer improved force delivery. This boosts efficiency significantly in heavy equipment. Their lightweight design enhances equipment maneuverability. Operators can notice the difference in handling.

Tips: Regular maintenance is crucial. Ensure lubricants are regularly applied. This keeps the cylinders functioning smoothly. Also, monitor performance metrics over time. Identify any inefficiencies early to address them.

The energy consumption of Shur Lift cylinders is usually lower. This translates to cost savings for operators. However, some may find the initial investment steep. It’s essential to weigh costs against long-term benefits. Proper training for operators can optimize overall performance. Keeping a close eye on metrics is vital. This encourages continuous improvement in operations.