+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

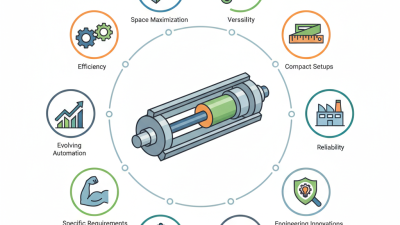

Hydro cylinders are vital in various industrial applications. They provide powerful, efficient movement in hydraulic systems. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $12.88 billion by 2025, driven by increasing demand for automation and machines in construction and agriculture.

John Smith, a renowned expert in hydraulic technology, once stated, "Hydro cylinders are the backbone of modern machinery." This highlights their importance in industries such as manufacturing and transportation. With these components, we achieve precision and effectiveness in movement.

However, not all applications utilize hydro cylinders optimally. Many industries face challenges in understanding the best practices for hydro cylinder use. This can lead to inefficiencies and increased maintenance costs. Despite their significance, the complexity of hydro cylinders can be daunting. Embracing their capabilities requires a mindset focused on continuous learning and improvement.

Hydraulic cylinders play a crucial role in industrial machinery and equipment. They are essential for converting hydraulic energy into mechanical power. One common application is in construction machinery. These cylinders lift, push, and pull heavy loads. In fact, the construction sector accounts for approximately 30% of the global hydraulic cylinder market, according to industry reports.

Another important application is in material handling equipment. Hydraulic cylinders enable efficient movement and placement of goods. They are integral in forklifts and conveyor systems. A report from an industry association notes that the material handling sector will grow by 5% annually through 2025. This growth highlights the increasing reliance on hydraulic technology.

**Tips:** Regular maintenance of hydraulic systems can prevent costly downtime. Inspect seals and hoses routinely. Additionally, choosing the right size and type of cylinder for specific tasks is vital. Misapplications can lead to system inefficiencies.

In the automotive industry, hydraulic cylinders are key in assembly lines. They help automate processes, speeding up production. However, challenges remain, such as ensuring precision in controlling these systems. Technology is evolving, but some manufacturers still struggle with integration. Proper training is essential for workers to utilize these advancements effectively.

| Application | Industry | Function | Common Features |

|---|---|---|---|

| Construction Equipment | Construction | Lifting and moving materials | Durable, high pressure rating |

| Agriculture Machinery | Agriculture | Plowing and harvesting | Weather resistant, compact |

| Material Handling Equipment | Logistics | Lifting and transporting goods | Fast response time, precision control |

| Mining Machinery | Mining | Extraction and drilling | High load capacity, reliability |

| Marine Equipment | Marine | Controlling ship functions | Corrosion resistant, robust design |

| Automotive Industry | Automotive | Assembly line operation | Precision movement, automation |

| Plastic Injection Molding | Manufacturing | Shaping plastic products | High speed, accuracy |

| Waste Management | Environmental | Compact and lift waste | High strength, efficiency |

| Steel Industry | Metallurgy | Manipulating heavy materials | Heavy-duty, reliable |

| Wind Turbines | Renewable Energy | Adjusting turbine blades | Weather proof, efficiency |

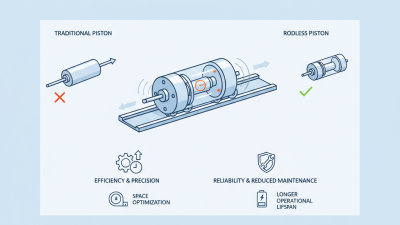

Hydro cylinders are essential in construction equipment. They excel in lifting, pushing, and pulling tasks. Their efficiency enhances productivity on job sites. More power means more work done in less time. This is critical in maintaining project timelines.

One key benefit is their durability. Hydro cylinders endure heavy loads and harsh conditions. Yet, they can be sensitive to maintenance issues. Neglecting regular checks can lead to failures. Hydraulic fluid leaks or damaged seals are common problems. These issues can halt operations unexpectedly.

Tips: Regularly inspect for leaks. Check seals and fluid levels. Early detection helps avoid costly downtime. Additionally, ensure that operators are trained in hydraulic systems. Improper use can lead to malfunctions and accidents.

Hydro cylinders also provide precise control. Operators can adjust power with ease. However, over-reliance on technology can create issues. It’s vital to balance automation and manual skill. Monitor performance closely to prevent overuse. These factors contribute to smoother operations.

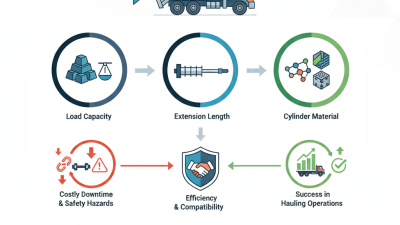

Hydro cylinders play a vital role in automotive manufacturing. They are essential for achieving precise movements in assembly lines. According to industry reports, about 70% of automation systems use hydraulic cylinders. This technology allows for smoother operation and improved speed. Efficient workflows lead to reduced production time and lower costs.

In automotive factories, hydro cylinders assist in various tasks. For instance, they lift heavy components with great accuracy. This is crucial when assembling delicate parts. However, inconsistencies in cylinder performance can lead to delays. Manufacturers must regularly maintain their hydraulic systems. Reports indicate that poor maintenance can decrease efficiency by up to 30%.

Safety is another concern in hydraulic operations. Sudden failures can pose serious risks to workers. Implementing proper monitoring systems can enhance safety. Shockingly, about 40% of accidents in manufacturing arise from hydraulic failures. Understanding these systems is important. It's not just about efficiency; it’s also about creating a safer work environment.

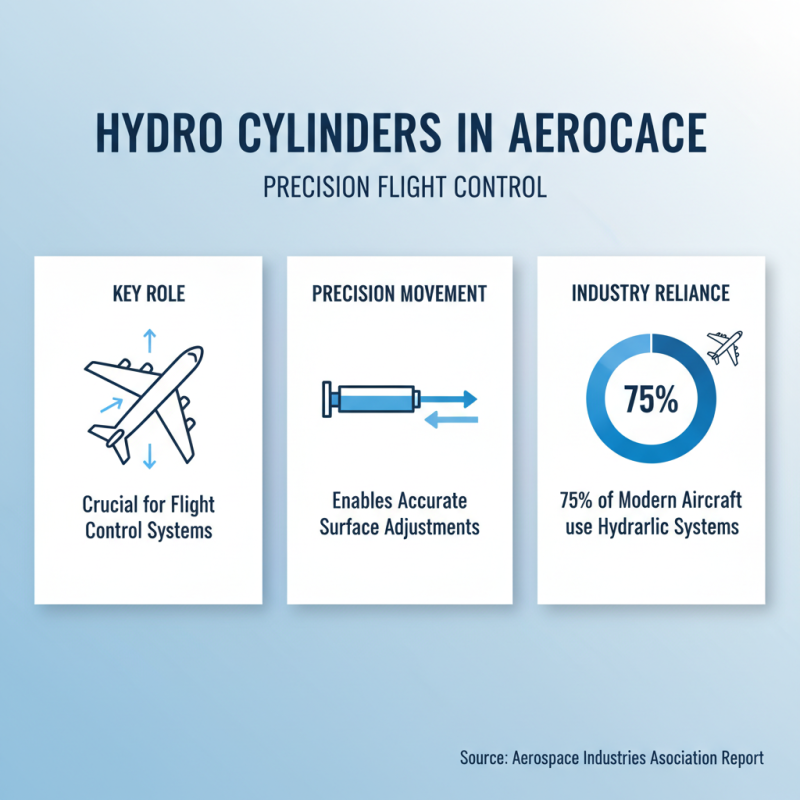

Hydro cylinders play a crucial role in aerospace, particularly in flight control systems. These systems rely on precise movements for their operations. According to a report from the Aerospace Industries Association, nearly 75% of modern aircraft use hydraulic systems to control flight surfaces. This reliance highlights the importance of hydro cylinders in maintaining structural integrity and performance during flight.

These components operate under extreme conditions and are vital for smooth and responsive control. For instance, hydro cylinders adjust ailerons and elevators. Without them, aircraft handling would be inefficient. In some test flights, malfunctions have occurred due to inadequate hydraulic pressure. Such issues show that even minor failures can lead to major concerns in aircraft safety and performance.

The integration of hydro cylinders in flight control systems ensures reliability. However, they also face challenges. For example, hydraulic fluid leaks can compromise various components. Moreover, manufacturers are continually working to minimize weight while enhancing performance. Each design iteration poses questions about durability and efficiency. Balancing these aspects is vital for future advancements in aerospace engineering.

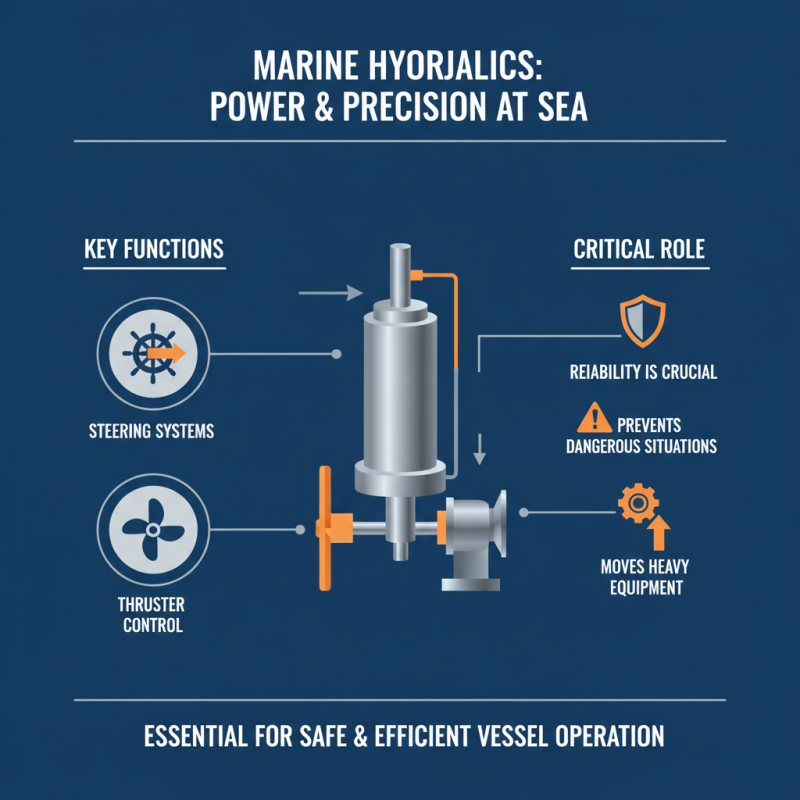

Hydraulic cylinders play a vital role in marine engineering. They are essential for controlling thrusters and steering systems on various vessels. These cylinders provide the necessary force to move and position heavy equipment. In high-stakes marine environments, reliability is crucial. A failure can lead to dangerous situations.

When it comes to thrusters, hydraulic cylinders offer precise control. They help in maneuvering ships during docking and undocking. This is important, especially in tight harbors. However, maintenance is often overlooked. Regular checks are needed to prevent malfunctions. Poor maintenance can lead to efficiency loss and safety hazards.

Steering systems in marine vessels also rely heavily on hydraulic cylinders. They ensure smooth navigation even under challenging conditions. The responsiveness of the system can sometimes falter. This can happen during extreme weather or heavy loads. Operators must remain vigilant. Understanding these limitations can improve risk management on the water.